Overview

304 stainless steel is a kind of universal stainless steel material, rust resistance is stronger than 200 series of stainless steel material, high temperature resistance is also better, can be up to 1000-1200 degrees.304 stainless steel has excellent corrosion resistance and corrosion resistance between grains.For oxidizing acid, in the experiment: concentration ≤65% boiling temperature of nitric acid, 304 stainless steel has a strong corrosion resistance.It also has good corrosion resistance to alkaline solution and most organic and inorganic acids.

Specification

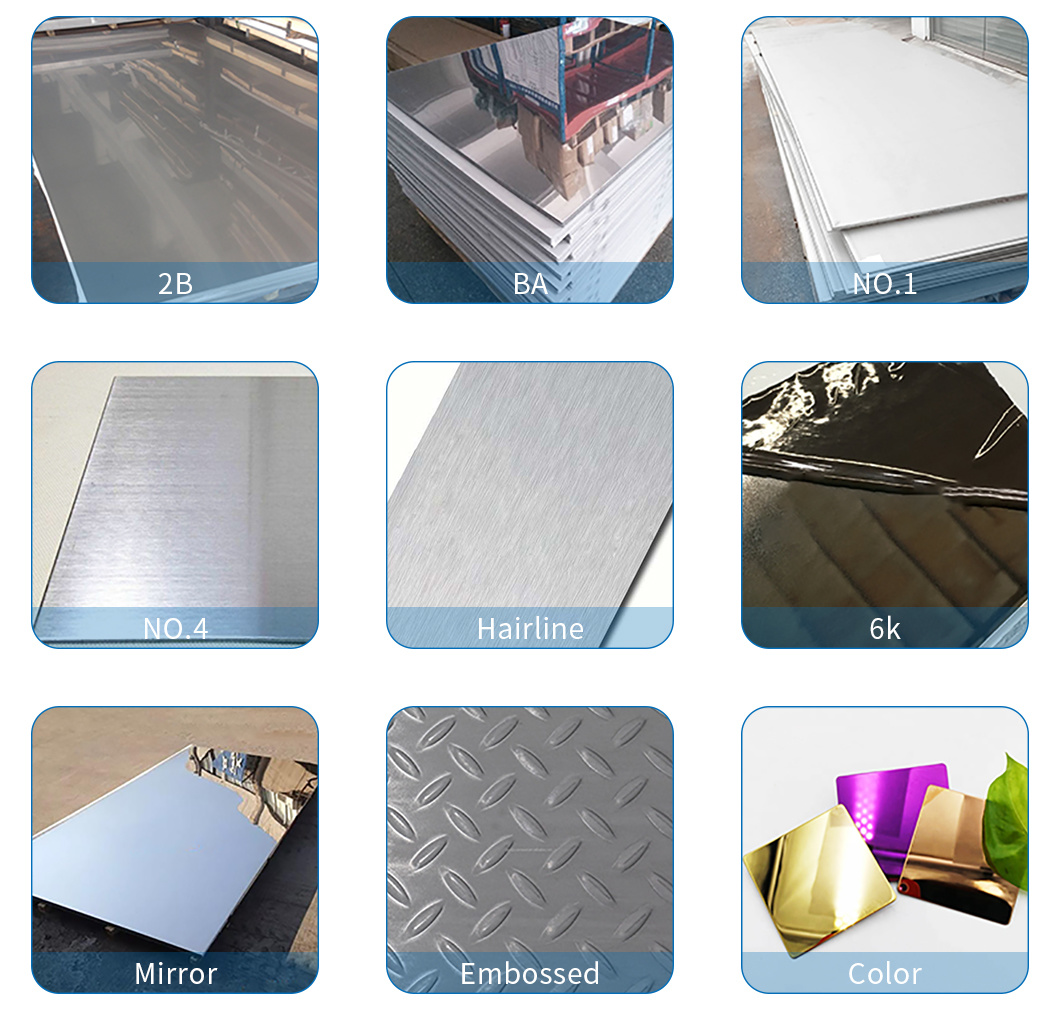

| Surface Finish | Description |

| 2B | A bright finish, after cold rolling, by heat treatment, can be used directly, or as a preliminary step to polish. |

| 2D | A dull surface, which results from cold rolling follow by annealing and descaling. It may get a final light roll pass through unpolished rolls. |

| BA | Bright Annealed finish which is obtained by annealing the material under an atmosphere so that scale is not produce on the surface. |

| No.1 | A rough, dull finish, which results from hot rolling to the specified thickness. Followed by annealing and descaling. |

| No.3 | This finish is polished by No.100 to No.120 abrasive specified in JIS R6001. |

| No.4 | This finish is polished by No.150 to No.180 abrasive specified in JIS R6001. |

| Hairline | A beautiful finish, protected by PVC film before using, used in kitchenware, |

| 8K Mirror | The “8” in 8K refers to the proportion of alloy components (304 stainless steel mainly refers to the content of elements), “K” refers to the grade of reflectivity after polishing. 8K mirror surface is the mirror surface grade reflected by chrome nickel alloy steel. |

| Embossed | Embossed stainless steel sheets are versatile materials used to create a decorative effect on the surface of a metal. They are an excellent option for architectural projects, splashbacks, signage, and more. They are extremely lightweight, and they can be shaped to meet the specifications of a variety of different applications. |

| Color | Colored Steel is titanium coated stainless steel. The colors are obtained by using a PVD derivate process. The forms on the surface of each sheet provides different types of coating, such as oxides, nitrides and carbides. |

The Main Uses are

1. Used for processing all kinds of conventional parts and for stamping die;

2. Used as high precision mechanical parts of steel;

3. It is widely used in the heat treatment process of stress relief annealing before bending.

4. It can be used as a building material for civil construction.

7. It can be used in automobile industry.

8. It can be applied to household appliance industry. The nuclear energy sector. Space and aviation. Electronic and electrical field. Medical machinery industry. The shipbuilding industry.

Chemical Composition of Common Used Stainless Steel

| Grade | C | Si | Mn | P | S | Ni | Cr | Mo | Others |

| 304 | ≤0.07 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/10.5 | 17.5/19.5 | ― | N≤0.10 |

| 304H | 0.04/0.10 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/10.5 | 18.0/20.0 | ― | |

| 304L | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/12.0 | 17.5/19.5 | ― | N≤0.10 |

| 304N | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/10.5 | 18.0/20.0 | ― | N:0.10/0.16 |

| 304LN | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/12.0 | 18.0/20.0 | ― | N:0.10/0.16 |

| 309S | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 12.0/15.0 | 22.0/24.0 | ― | |

| 310S | ≤0.08 | ≤1.50 | ≤2.00 | ≤0.045 | ≤0.030 | 19.0/22.0 | 24.0/26.0 | ― | |

| 316 | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 10.0/14.0 | 16.0/18.0 | 2.00/3.00 | N≤0.10 |

| 316L | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 10.0/14.0 | 16.0/18.0 | 2.00/3.00 | N≤0.10 |

| 316H | 0.04/0.10 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 10.0/14.0 | 16.0/18.0 | 2.00/3.00 | |

| 316LN | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 10.0/14.0 | 16.0/18.0 | 2.00/3.00 | N:0.10/0.16 |

| 317L | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 11.0/15.0 | 18.0/20.0 | 3.0/4.0 | N≤0.10 |

| 317LN | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 11.0/15.0 | 18.0/20.0 | 3.0/4.0 | N:0.10/0.22 |

| 321 | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 9.0/12.0 | 17.0/19.0 | ― | N≤0.10Ti:5ʷʢC+Nʣ/0.70 |

| 347 | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 9.0/13.0 | 17.0/19.0 | ― | Nb:10ʷC/1.00 |

| 904L | ≤0.020 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.035 | 23.0/28.0 | 19.0/23.0 | 4.00/5.00 | N≤0.10Cu:1.0/2.0 |

-

201 304 Mirror Color Stainless Steel Sheet in S...

-

316L 2B Chequered Stainless Steel Sheet

-

304 Colored Stainless Steel Sheet Etching Plates

-

430 Perforated Stainless Steel Sheet

-

SUS304 Embossed Stainless Steel Sheet

-

201 J1 J3 J5 Stainless Steel Sheet

-

Perforated Stainless Steel Sheets

-

PVD 316 Colored Stainless Steel Sheet

-

SUS304 BA Stainless Steel Sheets Best Rate

-

SUS316 BA 2B Stainless Steel Sheets Supplier