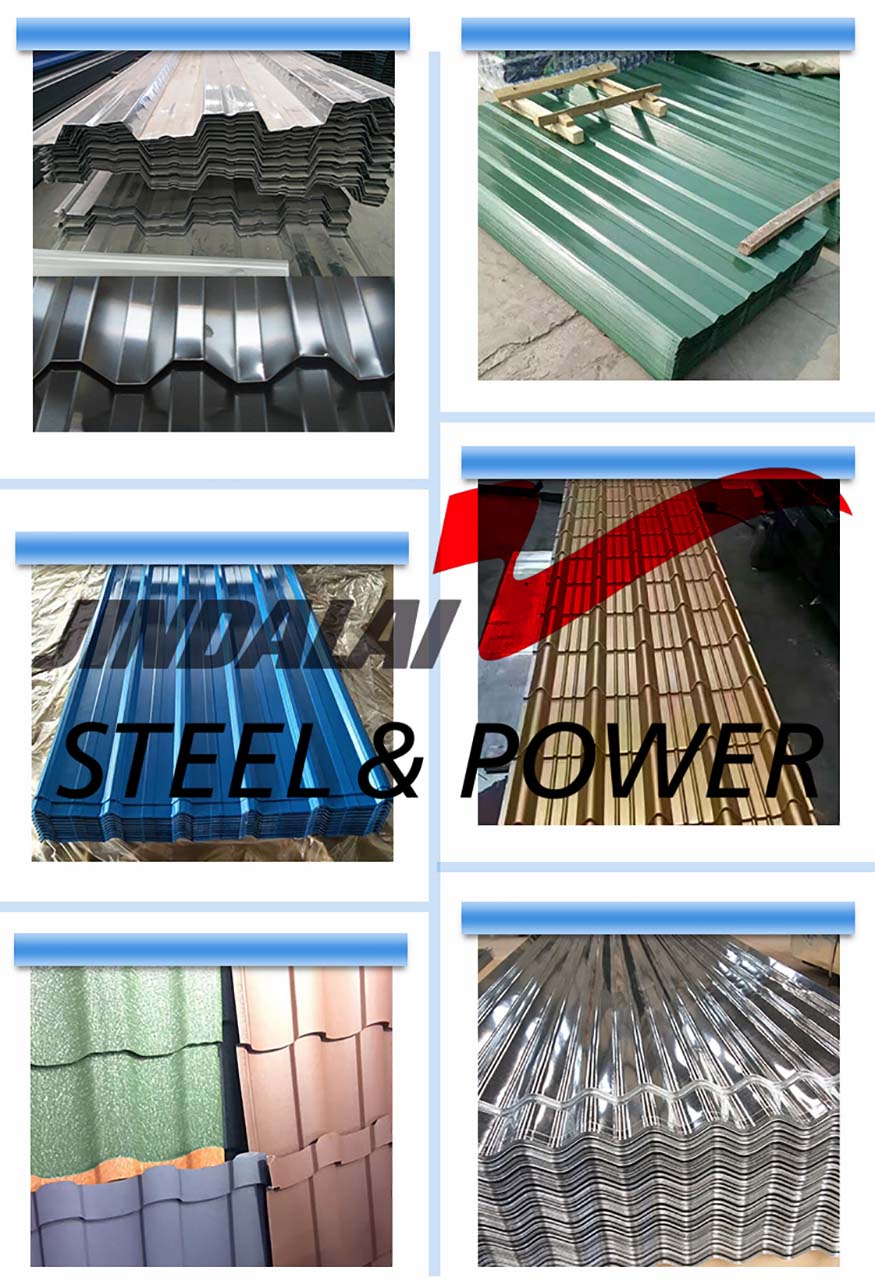

Overview of Pre-Painted Galvanized Steel Sheets (PPGI)

PPGI Sheets are sheets of pre-painted or pre-coated Steel that display high durability, and resistance against weather and UV rays from sunlight. As such, they are widely used as roofing sheets for buildings and construction. They do not undergo corrosion owing to atmospheric conditions and can be easily installed through a simple technique. PPGI Sheets are abbreviated from Pre-Painted Galvanised Iron. These sheets exhibit high strength and resilience and almost never leak or corrode. They are usually available in attractive colors and designs per preference. The metallic coating on these sheets are usually of Zinc or Aluminium. The thickness of this paint coating is usually between 16-20 microns. Surprisingly, PPGI Steel Sheets are very light weight and easy to manoeuvre.

Specification of Pre-Painted Galvanized Steel Sheets (PPGI)

| Name | Pre-Painted Galvanized Steel Sheets (PPGI) |

| Zinc Coating | Z120, Z180, Z275 |

| Paint Coating | RMP/SMP |

| Painting Thickness (top) | 18-20 microns |

| Painting Thickness (bottom) | 5-7 microns Alkyd baked coat |

| Surface Paint Reflection | Glossy finish |

| Width | 600mm-1250mm |

| Thickness | 0.12mm-0.45mm |

| Zinc Coating | 30-275g /m2 |

| Standard | JIS G3302 / JIS G3312 /JIS G3321/ ASTM A653M / |

| Tolerance | Thickness+/-0.01mm Width +/-2mm |

| Raw material | SGCC, SPCC, DX51D, SGCH,ASTM A653,ASTM A792 |

| Certificate | ISO9001.SGS/ BV |

Application

Industrial and civil construction, steel structure buildings and producing roofing sheets. Buildings like Detached Houses, Terraced Houses, Residential Multi-Storey Buildings, and Agricultural Constructions mainly have PPGI Steel Roofing. They can be fastened securely and they keep excess noise at bay. PPGI Sheets also have excellent thermal properties and thus can keep the interiors of a building warm during winter and cool during scorching heat.

Advantade

These roofing panels use the latest Cold Roll Form manufacturing process to provide a roof panel that has high heat insulation, weather-resistant, anti-fungal, anti-algae, anti-rust, high tensile strength that's capable of reforming back to its state, and light weight for ease of construction, fabrication, and quick installation. The roofing panels use a glossy textured lamination with a number of colours and different texture choices to provide both pleasing and aesthetic choices per the customer's personal choice. With these properties as a base, the roofing panels come with a multitude of selections that can accommodate many use cases. The roofing panels employ proprietary interlocking clip "Clip 730" clips that are interlocked between each roof panel while maintaining support with three fasteners. These fasteners are additionally concealed, which prevents them from affecting their pleasing looks.

Detail Drawing