Brief introduction

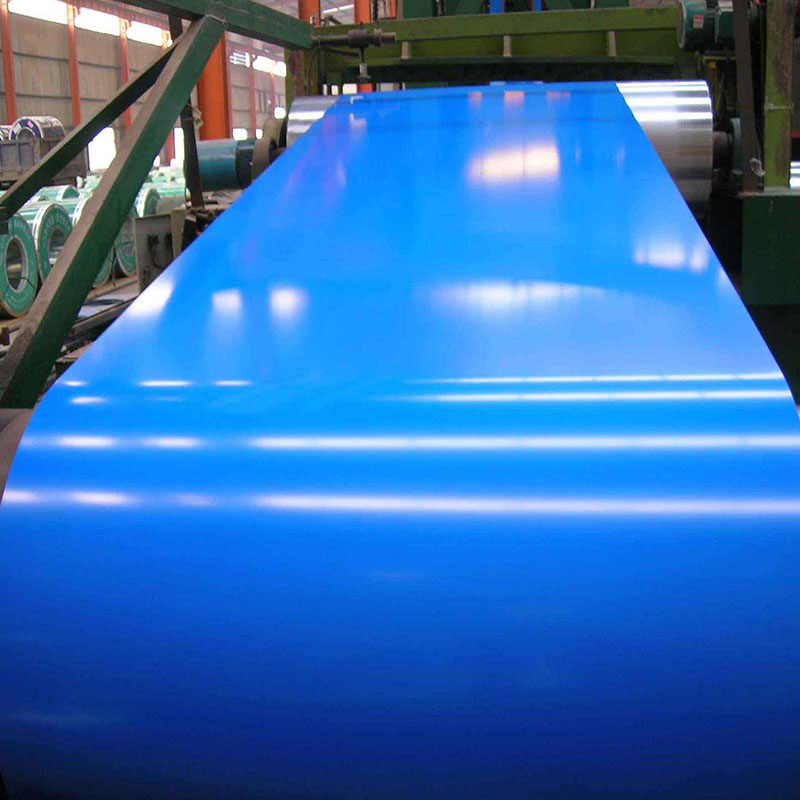

Prepainted steel sheet is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized steel sheets.

The base metals for prepainted steel sheet consist of cold-rolled, HDG electro-galvanized and hot-dip alu-zinc coated. The finish coats of prepainted steel sheets can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

The color of the prepainted steel sheet has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

The prepainted steel sheets can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

The prepainted steel sheets are mainly provided for various commercial purposes covering architectural construction, electrical household appliances, transportation, etc.

Type of coating structure

2/1: Coat the top surface of the steel sheet twice, coat the lower surface once, and bake the sheet twice.

2/1M: Coat and bake twice for both top surface and undersurface.

2/2: Coat the top/lower surface twice and bake twice.

Usage of different coating structures

3/1: The anti-corrosion property and scratch resistance of the single-layer backside coating is poor, however, its adhesive property is good. The prepainted steel sheet of this kind is mainly used for sandwich panel.

3/2M: Back coating has good corrosion resistance, scratch resistance and molding performance. Besides it has good adhesion and applicable for single layer panel and sandwich sheet.

3/3: The anti-corrosion property, scratch resistance and processing property of the backside coating of prepainted steel sheet is better, so it is widely used for roll forming. But its adhesive property is poor, so it is no used for sandwich panel.

Specification

| Name | PPGI Coils |

| Description | Prepainted Galvanized Steel Coil |

| Type | Cold rolled steel sheet, hot dipped zinc/al-zn coated steel sheet |

| Paint Color | Based on RAL No. or customers' color sample |

| Paint | PE,PVDF,SMP,HDP,etc and your special requirement to be discussed |

| Paint Thickness | 1. Top side: 25+/-5 micron 2. Back side: 5-7micron Or based on customers' requirement |

| Steel Grade | Base material SGCC or your requirement |

| Thickness Range | 0.17mm-1.50mm |

| Width | 914, 940, 1000, 1040, 1105, 1220, 1250mm or your requirement |

| Zinc Coating | Z35-Z150 |

| Coil Weight | 3-10MT, or as per customers' requests |

| Technique | Cold Rolled |

| Surface Protection |

PE, PVDF, SMP, HDP, etc |

| Application | Roofing, Corrugated Roofing Making, Structure, Tile Row Plate, Wall, Deep Drawing and Deep Drawn |

Detail drawing