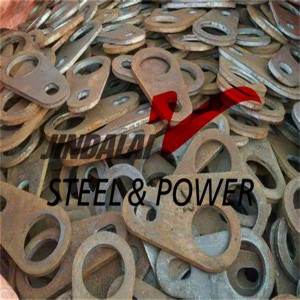

Specification of Metal Stamping Parts

| Product Name | Customized Metal Stamping Parts |

| Material | Steel, Stainless steel, Aluminum, Copper, Brass, etc |

| Plating | Ni Plating, Sn Plating, Cr Plating, Ag Plating, Au Plating, electrophoretic paint etc. |

| Standard | DIN GB ISO JIS BA ANSI |

| Design file format | Cad, jpg, pdf etc. |

| Major Equipments | --AMADA Laser cutting machine --AMADA NCT punching machine --AMADA bending machines --TIG/MIG welding machines --Spot welding machines --Stamping machines (60T ~ 315T for progress and 200T~600T for robot transfer) --Riveting machine --Pipe cutting machine --Drawing mill --Stamping tools make maching(CNC milling machine, Wire-cut, EDM, Grinding machine) |

| Press machine tonnage | 60T to 315(Progress)and 200T~600T (Robot treansfer) |

Advantage of Metal Stamping Parts

● Stamping die is a production and processing method with high productivity and low raw material consumption. Stamping die design is suitable for the production of a large number of parts and handicrafts, which is conducive to maintaining technical specialization and automation, and has a high productivity. In addition, stamping die production and manufacturing can not only redouble efforts to produce with less waste and no waste, but also can be flexibly used even with leftover materials in some cases.

● The actual operation and processing technology are convenient, and the operator is not required to have high-quality workmanship.

● The parts produced by stamping die generally do not need machining, so the specification accuracy is high.

● Metal stampings shall have good tolerance. The processing reliability of stamping parts is good. The same batch of metal stamping parts can be used interchangeably without endangering the assembly line and commodity characteristics.

● As metal stamping parts are made of plates, their process performance is good, which provides a convenient standard for the process of subsequent metal surface treatment (such as electroplating and spraying).

● Stamped parts can be processed to obtain parts with high compressive strength, high bending stiffness and light weight.

● The cost of mass production of metal stamping parts with abrasive tools is low.

● The stamping die can produce complex parts that are difficult to produce by laser cutting other metal materials.

Detail Drawing