Overview of SS201

201 stainless steel in China contains 5 types J1, J2, J3, J4 and J5 with different composition and application. In order to make the customer well known the difference, we will make a simple introduction here.

l Origin of SS201:

Birth: Series 200 stainless steel was born during World War II as a replacement for Series 300 stainless steel which was first developed successfully in the United States.

l Development of SS201:

The indians who original participated in the United States to develop 200 series of stainless steel made 200 series further developed, they study from India's own resources---rich in manganese resources, and lack of nickel.

l China SS201

201 series of stainless steel in China mainly include J4, J1, J3, J2, J5. In the early years, we named high copper (J4), and semi-copper (J1) to distinguish 201 steel, but with the downward development of copper content, there is a replacement of J1 and J3, and then the birth of J2 and J5 to replace J3.

Specification of SS201

| Grade | 201J1, J2, J3, J4, J5 304, 430, 316L etc |

| Standard | JIS,AISI,ASTM,TUV |

| Thickness | 0.1~200mm |

| Width | 10~2000mm |

| Length | customized |

| Surface | Bead blasting,mirror,colored |

| Color | Rose gold, gold, black,red,etc |

| PVC | 7c pvc or customized |

| Processing | Bending, Welding, Decoiling, Punching, Cutting |

| Width | 10~2500mm |

| Delivery | 10~15 days |

| Packing | Wooden pallet |

| Moq | 1 MT |

| Business type | Factory directly sell |

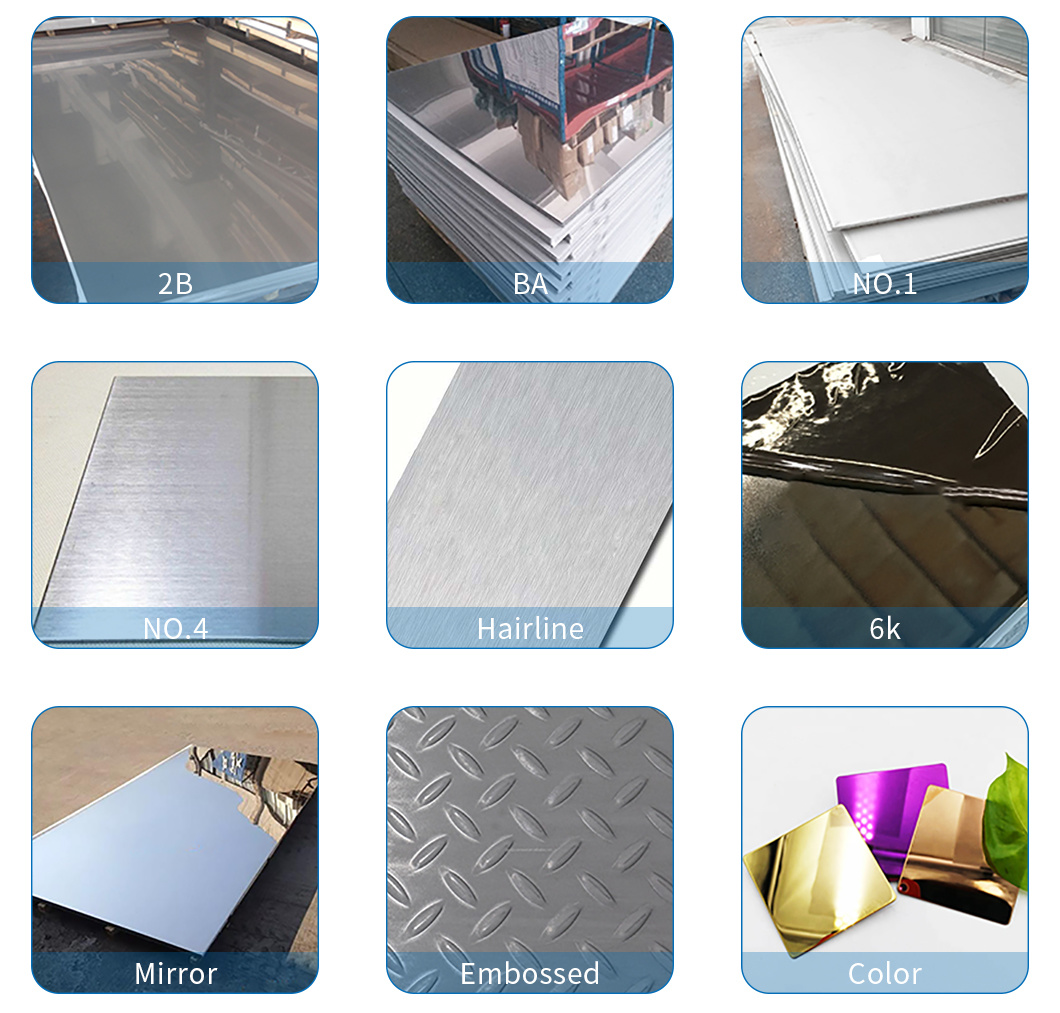

Details of Surface Treatment

1D -- The surface has discontinuous granular shape, also known as fog surface.

Processing technology: hot rolling + annealing shot peening pickling + cold rolling + annealing pickling.

2D - A slightly silvery white colour.

Processing technology: hot rolling + annealing shot peening pickling + cold rolling + annealing pickling.

2B -- Silver white with better gloss and flatness than a 2D surface.

Processing technology: hot rolling + annealing shot peening pickling + cold rolling + annealing pickling + quenching and tempering rolling.

Ba - Excellent surface gloss, high reflectivity, like a mirror surface.

Processing technology: hot rolling + annealing shot peening pickling + cold rolling + annealing pickling + surface polishing + quenching and tempering rolling.

No.3 -- Good gloss, coarse grain surface.

Processing technology: polishing and tempering rolling for 2D or 2B with 100~120 abrasive materials (JIS R6002).

No.4 -- Good gloss, fine lines on the surface.

Processing process: polishing and tempering rolling for 2D or 2B with 150~180 abrasive materials (JIS R6002).

HL -- Silver grey with hair streaks.

Processing technology: 2D products or 2B products with appropriate granularity of abrasive materials for polishing the surface is a continuous abrasive grain.

MIRRO -- Specular.

Processing technology: 2D products or 2B products with appropriate granularity of the grinding material grinding and polishing to the mirror effect.

Service of Jindalai steel

l OEM&ODM, also provide customized service.

l Offer for your unique design and some our current model.

l Protection of your sales area, ideas of design and all your private information.

l Provide strict quality check for each part , each process before export.

l Provide complete post-sale service, including installation , technical guide.

l Cut to length

l Despoiling and slitting

l Grinding and brushing

l Film protection

l Plasma and water jet cutting

l Embossing

l Mirror or others finish

-

201 304 Mirror Color Stainless Steel Sheet in S...

-

316L 2B Chequered Stainless Steel Sheet

-

304 Colored Stainless Steel Sheet Etching Plates

-

430 Perforated Stainless Steel Sheet

-

SUS304 Embossed Stainless Steel Sheet

-

201 J1 J3 J5 Stainless Steel Sheet

-

Perforated Stainless Steel Sheets

-

PVD 316 Colored Stainless Steel Sheet

-

SUS304 BA Stainless Steel Sheets Best Rate

-

SUS316 BA 2B Stainless Steel Sheets Supplier

-

430 BA Cold Rolled Stainless Steel Plates

-

Customized Perforated 304 316 Stainless Steel P...