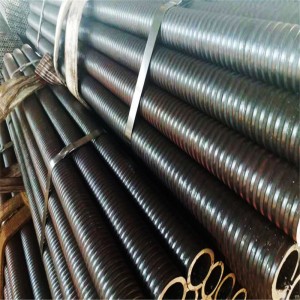

Overview of the Anchor Hollow Steel Bars

Anchor hollow steel bars are produced in sections with standard lengths of 2.0, 3.0 or 4.0 m. The standard outer diameter of the hollow steel bars ranges from 30.0 mm to 127.0 mm. If necessary, hollow steel bars are continued with coupling nuts. Different types of sacrificial drill bits are used depending on the type of soil or rock mass. A hollow steel bar is better than a solid bar with the same cross-sectional area because of its better structural behavior in terms of buckling, circumference and bending stiffness. The result is a higher buckling and flexural stability for the same amount of steel.

Specification of Self Drilling Anchor Rods

| Specification | R25N | R32L | R32N | R32/18.5 | R32S | R32SS | R38N | R38/19 | R51L | R51N | T76N | T76S |

| Outside diameter (mm) | 25 | 32 | 32 | 32 | 32 | 32 | 38 | 38 | 51 | 51 | 76 | 76 |

| Internal diameter, average(mm) | 14 | 22 | 21 | 18.5 | 17 | 15.5 | 21 | 19 | 36 | 33 | 52 | 45 |

| External diameter, effective(mm) | 22.5 | 29.1 | 29.1 | 29.1 | 29.1 | 29.1 | 35.7 | 35.7 | 47.8 | 47.8 | 71 | 71 |

| Ultimate load capacity (kN) | 200 | 260 | 280 | 280 | 360 | 405 | 500 | 500 | 550 | 800 | 1600 | 1900 |

| Yield load capacity (kN) | 150 | 200 | 230 | 230 | 280 | 350 | 400 | 400 | 450 | 630 | 1200 | 1500 |

| Tensile strength, Rm(N/mm2) | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 |

| Yield strength, Rp0, 2(N/mm2) | 650 | 650 | 650 | 650 | 650 | 650 | 650 | 650 | 650 | 650 | 650 | 650 |

| Weight (kg/m) | 2.3 | 2.8 | 2.9 | 3.4 | 3.4 | 3.6 | 4.8 | 5.5 | 6.0 | 7.6 | 16.5 | 19.0 |

| Thread type (left-hand ) | ISO 10208 | ISO 1720 | MAI T76 standard | |||||||||

| Steel grade | EN 10083-1 | |||||||||||

Applications of Self Drilling Anchor Rods

In recent years, with the increasing demand for geotechnical support, drilling equipment has been constantly updated and developed. At the same time, labor and rental costs have increased, and the requirements for construction period have become increasingly high. In addition, the use of self drilling hollow anchor rods in geological conditions prone to collapse has excellent anchoring effects. These reasons have led to the increasingly widespread application of self drilling hollow anchor rods. Self drilling hollow anchor rods are mainly used in the following scenarios:

1. Used as prestressed anchor rod: used in scenarios such as slopes, underground excavation, and anti floating to replace anchor cables. Self drilling hollow anchor rods are drilled to the required depth, and then end grouting is carried out. After solidification, tension is applied;

2. Used as micropiles: Self drilling hollow anchor rods can be drilled and grouted downwards to form micropiles, commonly used in wind power plant tower foundations, transmission tower foundations, building foundations, retaining wall pile foundations, bridge pile foundations, etc;

3. Used for soil nails: commonly used for slope support, replacing conventional steel bar anchor rods, and can also be used for deep foundation pit steep slope support;

4. Used for rock nails: In some rock slopes or tunnels with severe surface weathering or joint development, self drilling hollow anchor rods can be used for drilling and grouting to bond rock blocks together to improve their stability. For example, rock slopes of highways and railways that are prone to collapse can be reinforced, and conventional pipe sheds can also be replaced for reinforcement at loose tunnel openings;

5. Basic reinforcement or disaster management. As the support time of the original geotechnical support system increases, these support structures may encounter some problems that require reinforcement or treatment, such as deformation of the original slope, settlement of the original foundation, and uplift of the roadway surface. Self drilling hollow anchor rods can be used to drill into the original slope, foundation, or roadway ground, etc., for grouting and consolidation of cracks, to prevent the occurrence of geological disasters.