Specification of Ductile Iron Pipe

| Product Name | Self anchored ductile iron, Ductile Iron Pipe with Spigot & Socket |

| Specifications | ASTM A377 Ductile Iron, AASHTO M64 Cast Iron Culvert Pipes |

| Standard | ISO 2531, EN 545, EN598, GB13295, ASTM C151 |

| Grade | C20, C25, C30, C40, C64, C50, C100 & Class K7, K9 & K12 |

| Length | 1-12 Meters or as the requirement of the customer |

| Sizes | DN 80 mm to DN 2000 mm |

| Joint Method | T type; Mechanical joint k type; Self-anchor |

| External Coating | Red / Blue Epoxy or Black Bitumen, Zn & Zn-AI Coatings, Metallic Zinc (130 gm/m2 or 200 gm/m2 or 400 gm/m2 as per the customer’s requirements) complying to relevant ISO, IS, BS EN standards with a finishing layer of Epoxy Coating / Black Bitumen(minimum thickness 70 micron) as per the customer’s requirements. |

| Internal Coating | Cement Lining of OPC/ SRC/ BFSC/ HAC Cement mortar lining as per requirement with ordinary Portland Cement and Sulphate Resisting Cement conforming to relevant IS, ISO, BS EN standards. |

| Coating | Metallic zinc spray with Bituminous Coating (Outside) Cement mortar lining (Inside). |

| Application | Ductile cast iron Pipe are mainly used for transferring waste water, drinkable water and for irrigation. |

Ductile Iron Grade Comparison

| Grade | Tensile Strength (psi) | Yield Strength (psi) | Elongation | Fatigue Strength (psi) | Extended Size Range |

| 65-45-12 > | 65,000 | 45,000 | 12 | 40,000 | |

| 65-45-12X > | 65,000 | 45,000 | 12 | 40,000 | Yes |

| SSDI > | 75,000 | 55,000 | 15 | 40,000 | |

| 80-55-06 > | 80,000 | 55,000 | 6 | 40,000 | |

| 80-55-06X > | 80,000 | 55,000 | 6 | 40,000 | Yes |

| 100-70-03 > | 100,000 | 70,000 | 3 | 40,000 | |

| 60-40-18 > | 60,000 | 40,000 | 18 | n/a |

Properties of Ductile Iron Pipe

| Physical Properties of Ductile Iron | |

| Density | 7100 Kg/m3 |

| Co-efficient of Thermal Expansion | 12.3X10-6 cm/cm/0C |

| Mechanical properties | Ductile Iron |

| Tensile Strength | 414 MPa to 1380 MPa |

| Yield Strength | 275 MPa to 620 MPa |

| Young’s Modulus | 162-186 MPa |

| Poisson’s Ratio | 0.275 |

| Elongation | 18% to 35% |

| Brinell Hardness | 143-187 |

| Charpy unnotched impact strength | 81.5 -156 Joules |

Advantages of Ductile Iron Pipe

Greater ductility than cast iron

Greater impact resistance than cast iron

Greater strength than cast iron

Lighter and easier to lay than cast iron

Simplicity of joints

Joints can accommodate some angular deflection

Low pumping costs due to large nominal inside diameter

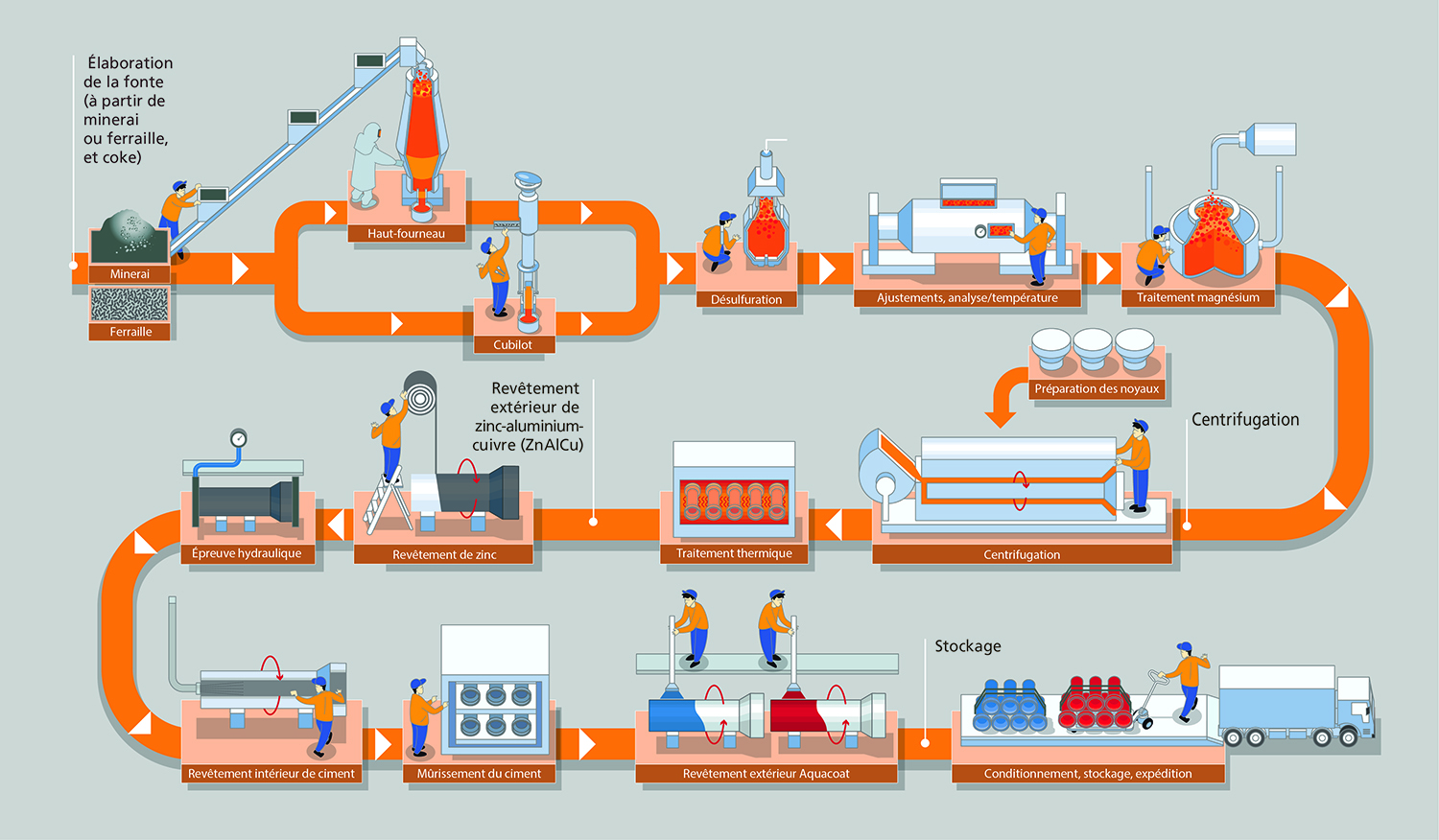

Production process of Ductile Iron Pipe

Our Product Range Include

• Ductile Iron Pipes & Fittings to BS 4772, ISO 2531, EN 545 for Water

• Ductile Iron Pipes & Fittings to EN 598 for Sewerage

• Ductile Iron Pipes & Fittings to EN969 for Gas

• Flanging & Welding of Ductile Iron Pipes.

• All kinds of job casting to customers’ standard.

• Flange Adaptor & Coupling.

• Universal Flange Adaptor

• Cast Iron Pipes & Fittings to EN877, CISPI: 301/CISPI: 310.