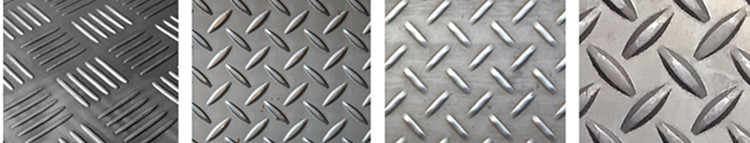

Overview of Embossed Stainless Steel Sheet

Embossed stainless steel sheets have many applications, we typically use Squares for table tops, display shelving, panelling and kitchen wall cladding. Embossed, Rigidised stainless steel sheet is durable, long lasting and anti vandal, the patterns are attractive and offer designers a unique material with which to work.

Specification of Embossed Stainless Steel Sheet

| Standard: | JIS, AiSi, ASTM, GB, DIN, EN. |

| Thickness: | 0.1 mm – 200.0 mm. |

| Width: | 1000mm, 1220mm, 1250mm, 1500mm |

| Length: | 2000mm, 2438mm, 3048mm, Customized. |

| Tolerance: | ±0.1%. |

| SS Grade: | 304, 316, 201, 430, etc. |

| Technique: | Cold Rolled. |

| Finish: | PVD Color + Mirror + Stamped. |

| Colors: | Champagne, Copper, Black, Blue, Silver, Gold, Rose Gold. |

| Edge: | Mill, Slit. |

| Applications: | Ceiling, Wall Cladding, Facade, Background, Elevator Interior. |

| Packing: | PVC + Waterproof Paper + Wooden Package. |

Benefits Of Embossed Stainless Steel Metal Sheets

l Durability

The stamping process used on the stainless steel makes it not only eye-catching but also durable. Though the metal material should be soften to make it easy to form a pattern in the concave-convex die, once the material low down to the normal temperature after processing, the finished product will come out with raised-recessed shape with more durability and toughness.

l High Recognition

Embossed stainless steel and metal sheet products play an essential role on decoration with artistic or religious element, as the embossed patterns on it can be design according to whatever you want to present in your space. As the can create a strong visual effect to make people impressed.

l Slip Resistance

Some embossed metal sheets are used for floor due to not only their outstanding durability for withstanding heavy weight, but also their rugged surface for resistance to slip. It’s perfectly suitable for being used for somewhere with high traffic like outdoor walkways, ramps, commercial kitchens, public restrooms, and more. It can prevent people from slip and fall accidents.

l Cost Effectiveness

Unlike the perforated metal, expanded metal sheet is processed to create opening holes without wastage of material, there is no scrap metal when the expanded sheet comes out, this will lower your material costs. And expanded stainless steel sheets are processed by being integrally stretched, one sheet can be expanded out to form a much larger piece, so you don’t need to do more process to join them together, this mean that you can cost less on the labor.

l Workability

Embossing is an efficient work compared to other fabrication methods. The different patterns and styles should not be difficult to be formed on its surface, and make it easier to work out with high precision, it is not difficult to complete your embossing process.

l Flexible Customizability

There is endless possibility to make various patterns and styles according to your imaginations and ideas. You can get some regular round or diamond-shapes aligned on the surface for some practical purposes. Also, you can do some patterns such as some animals, plants, and some intricate images and texts on it to express some special meanings.

-

430 Perforated Stainless Steel Sheet

-

SUS304 Embossed Stainless Steel Sheet

-

201 304 Mirror Color Stainless Steel Sheet in S...

-

201 J1 J3 J5 Stainless Steel Sheet

-

304 Colored Stainless Steel Sheet Etching Plates

-

316L 2B Chequered Stainless Steel Sheet

-

Perforated Stainless Steel Sheets

-

PVD 316 Colored Stainless Steel Sheet

-

SUS304 BA Stainless Steel Sheets Best Rate

-

SUS316 BA 2B Stainless Steel Sheets Supplier