The Grade of High Steel Carbon Plate

| ASTM A283/A283M | ASTM A573/A573M | ASME SA36/SA36M |

| ASME SA283/SA283M | ASME SA573/SA573M | EN10025-2 |

| EN10025-3 | EN10025-4 | EN10025-6 |

| JIS G3106 | DIN 17100 | DIN 17102 |

| GB/T16270 | GB/T700 | GB/T1591 |

Take A36 Applications as An Example

Application of ASTM A36 Carbon Structural Steel Plate

| Machinery Parts | Frames | Fixtures | Bearing Plates | Tanks | Bins | Bearing Plates | Forgings |

| Base Plates | Gears | Cams | Sprockets | Jigs | Rings | Templates | Fixtures |

| ASTM A36 Steel Plate Fabrication Options | |||||||

| Cold Bending | Mild Hot Forming | Punching | Machining | Welding | Cold Bending | Mild Hot Forming | Punching |

Chemical Composition of A36

| ASTM A36 Hot Rolled Steel Plate |

Chemical Compostion | |

| Element | content | |

| Carbon, C | 0.25 - 0.290 % | |

| Copper, Cu | 0.20 % | |

| Iron, Fe | 98.0 % | |

| Manganese, Mn | 1.03 % | |

| Phosphorous, P | 0.040 % | |

| Silicon, Si | 0.280 % | |

| Sulfur, S | 0.050 % | |

Physical Property of A36

| Physical Property | Metric | Imperial |

| Density | 7.85 g/cm3 | 0.284 lb/in3 |

Mechanical Property of A36

| ASTM A36 Hot Rolled Steel Plate | ||

| Mechanical Properties | Metric | Imperial |

| Tensile Strength, Ultimate | 400 - 550 MPa | 58000 - 79800 psi |

| Tensile Strength, Yield | 250 MPa | 36300 psi |

| Elongation at Break (in 200 mm) | 20.0 % | 20.0 % |

| Elongation at Break (in 50 mm) | 23.0 % | 23.0 % |

| Modulus of Elasticity | 200 GPa | 29000 ksi |

| Bulk Modulus (typical for steel) | 140 GPa | 20300 ksi |

| Poissons Ratio | 0.260 | 0.260 |

| Shear Modulus | 79.3 GPa | 11500 ksi |

Carbon steel is an alloy consisting of iron and carbon. Several other elements are allowed in carbon steel, with low maximum percentages. These elements are manganese, with a 1.65% maximum, silicon, with a 0.60% maximum, and copper, with a 0.60% maximum. Other elements may be present in quantities too small to affect its properties.

There are four types ofcarbon steel

Based on the amount of carbon present in the alloy. Lower carbon steels are softer and more easily formed, and steels with a higher carbon content are harder and stronger, but less ductile, and they become more difficult to machine and weld. Below are the properties of the grades of carbon steel we supply:

● Low Carbon Steel–Composition of 0.05%-0.25% carbon and up to 0.4% manganese. Also known as mild steel, it is a low-cost material that is easy to shape. While not as hard as higher-carbon steels, car burizing can increase its surface hardness.

● Medium Carbon Steel – Composition of 0.29%-0.54% carbon, with 0.60%-1.65% manganese. Medium carbon steel is ductile and strong, with long-wearing properties.

● High Carbon Steel– Composition of 0.55%-0.95% carbon, with 0.30%-0.90% manganese. It is very strong and holds shape memory well, making it ideal for springs and wire.

● Very High Carbon Steel - Composition of 0.96%-2.1% carbon. Its high carbon content makes it an extremely strong material. Due to its brittleness, this grade requires special handling.

Detail drawing

-

A36 Hot Rolled Steel Plate Factory

-

Q345, A36 SS400 Steel Coil

-

ASTM A36 Steel Plate

-

ASTM A653 Z275 Galvanized Steel Coil China Factory

-

S355 Structural Steel Plate

-

S355G2 Offshore Steel Plate

-

S355J2W Corten Plates Weathering Steel Plates

-

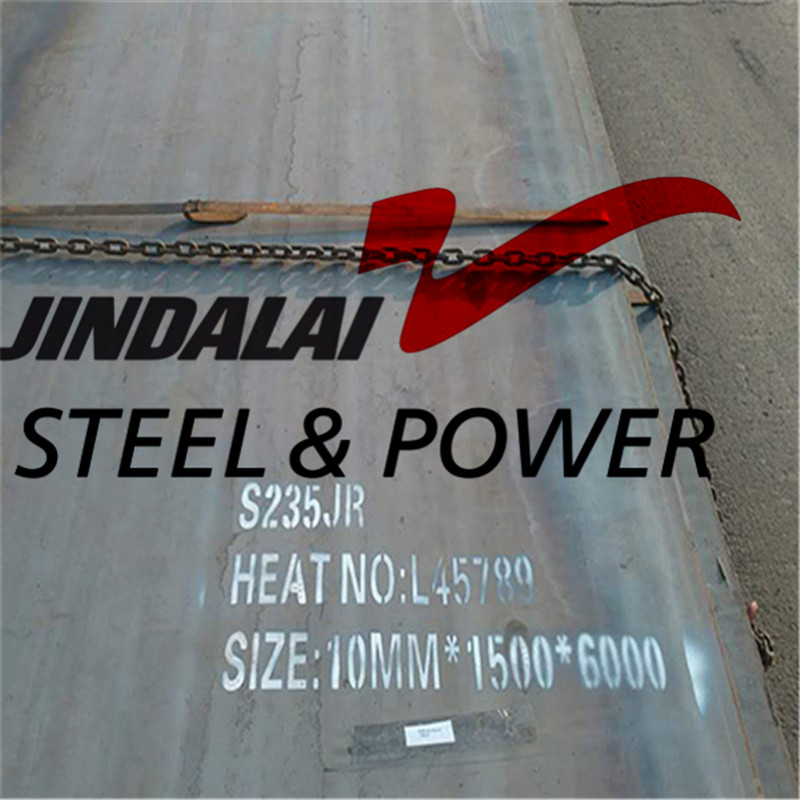

S235JR Carbon Steel Plates/MS Plate

-

SS400 Q235 ST37 Hot Rolled Steel Coil

-

Checkered Steel Plate

-

Hot Rolled Galvanized Checkered Steel Plate

-

MILD STEEL (MS) CHECKERED PLATE

-

Hot Rolled Chequered Coil/Ms Checkered Coils/HRC