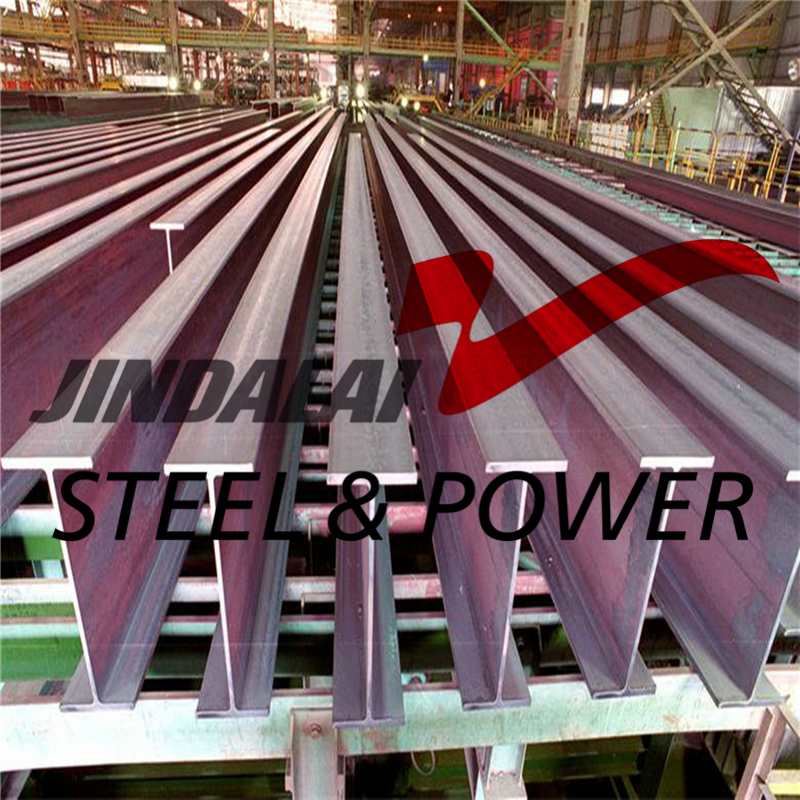

Overview of ASTM A36 H Beam

ASTM A36 H beam steel is a low carbon steel that exhibits good strength coupled with formability. It is easy to machine and fabricate and can be securely welded. A36 H beam steel can be galvanized to provide increased corrosion resistance. Yield strength of ASTM A36 is less than that of cold roll C1018, thus enabling ASTM A36 to bend more readily than C1018. Normally, larger diameters in ASTM A36 are not produced since C1018 hot roll rounds are used.

Specification of ASTM A36 H Beam

| Standard | BS EN 10219 - Cold Formed Welded Structural Hollow Sections of Non-alloy and Fine Grain Steels |

| Grade | S235JRH |

| SHS (Square Hollow Sections) Sizes | 20*20mm-400*400mm |

| Wall Thickness | 0.5mm - 25mm |

| Length | 6000-14000 mm |

| Type | Seamless/ Welded / ERW |

| Packing | In bundles, Anti-corrosion heat preservation, Varnish coating, Ends can be bevelled or square cut, End Capped Certification & supplementary test, Finishing & Identity Mark |

| Surface Protection | Black (Self Coloured uncoated), Varnish/Oil Coating, Pre-Galvanized, Hot Dip Galvanized |

Chemical Composition of A36 Steel Properties

| A36 Material Chemical Composition (%, ≤), for Plates, Width > 380 mm (15 in.) | |||||||||||||

| Steel | C | Si | Mn | P | S | Cu | Thickness (d), mm (in.) | ||||||

| ASTM A36 | 0.25 | 0.40 | no requirement | 0.03 | 0.03 | 0.20 | d ≤20 (0.75) | ||||||

| 0.25 | 0.40 | 0.80-1.20 | 0.03 | 0.03 | 0.20 | 20<d≤40 (0.75<d≤ 1.5) | |||||||

| 0.26 | 0.15-0.40 | 0.80-1.20 | 0.03 | 0.03 | 0.20 | 40<d≤65 (1.5<d≤2.5) | |||||||

| 0.27 | 0.15-0.40 | 0.85-1.20 | 0.03 | 0.03 | 0.20 | 65<d≤100 (2.5<d≤ 4) | |||||||

| 0.29 | 0.15-0.40 | 0.85-1.20 | 0.03 | 0.03 | 0.20 | > 100 (4) | |||||||

| A36 Material Chemical Composition (%, ≤), for Plates & Bars, Width ≤ 380 mm (15 in.) | |||||||||||||

| Steel | C | Si | Mn | P | S | Cu | Thickness (d), mm (in.) | ||||||

| ASTM A36 | 0.26 | 0.40 | no requirement | 0.04 | 0.05 | 0.20 | d ≤ 20 (0.75) | ||||||

| 0.27 | 0.40 | 0.60-0.90 | 0.04 | 0.05 | 0.20 | 20< d≤ 40 (0.75< d≤ 1.5) | |||||||

| 0.28 | 0.40 | 0.60-0.90 | 0.04 | 0.05 | 0.20 | 40< d≤ 100 (1.5< d≤ 4) | |||||||

| 0.29 | 0.40 | 0.60-0.90 | 0.04 | 0.05 | 0.20 | > 100 (4) | |||||||