What is Abrasion Resistant Steel Plates

Abrasion resistant (AR) steel plate is a high-carbon alloy steel plate. This means that AR is harder due to the addition of carbon, and formable and weather resistant due to added alloys.

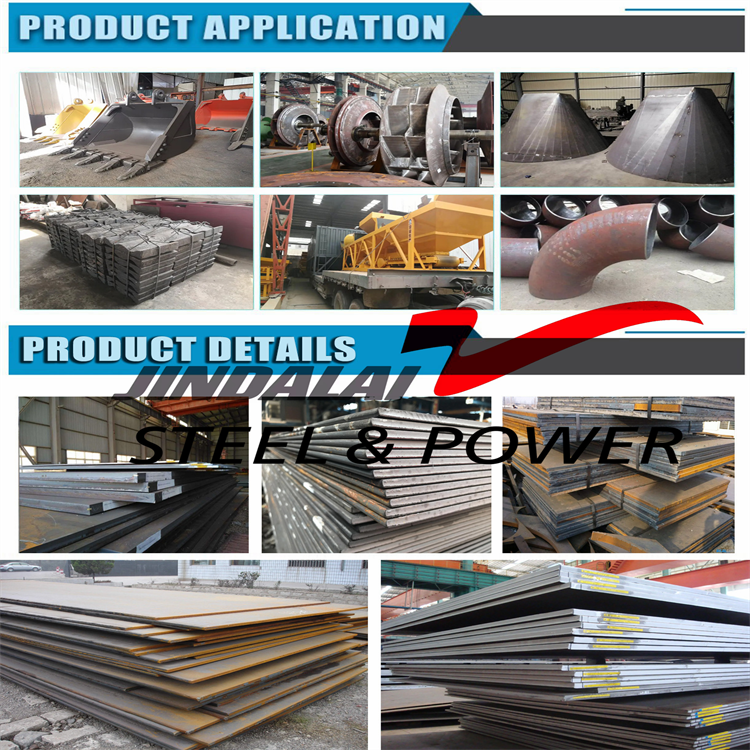

Carbon added during the formation of the steel plate substantially increases toughness and hardness but reduces strength. Therefore, AR plate is used in applications where abrasions and wear and tear are the main causes of failure, such as industrial manufacturing, mining, construction and material handling. AR plate is not ideal for structural construction uses like support beams in bridges or buildings.

Abrasion Resistant Steel Jindalai Can Supply

| AR200 |

| AR200 steel is an abrasion resistant medium steel plate. It is medium-carbon manganese steel with a moderate hardness of 212-255 Brinell Hardness. AR200 can be machined, punched, drilled, and formed and is known to be an inexpensive abrasion-resistant material. Typical applications are material chutes, material moving parts, truck liners. |

| AR235 |

| AR235 carbon steel plate has a nominal hardness of 235 Brinell Hardness. This steel plate is not meant for structural applications, but it is intended for moderate wear applications. Some typical applications are bulk material handling chute liners, skirt board liners, cement mixer drums and fins, and screw conveyors. |

| AR400 AR400F |

| AR400 steel is designed for abrasion and wear-resistant applications. The high-carbon alloy steel grades are determined on the hardness of the steel. The AR400 steel plate is often used in applications where abrasion-resistant, formability, and weldability are required. Some typical industries are mining, material handling equipment, and aggregate. |

| AR450 AR450F |

| AR450 steel plate is an alloy composed of different elements, including carbon and boron. It offers more hardness than the AR400 steel plate while maintaining good formability, ductility, and impact resistance. Therefore, it is commonly used in moderate to heavy wear applications like bucket components, construction equipment, and dump body trucks. |

| AR500 AR500F |

| AR500 steel plate is a high-carbon steel alloy and has a surface hardness of 477-534 Brinell Hardness. This increase in strength and abrasion resistance provides a greater impact and sliding resistance but will make the steel less malleable. AR500 can resist wear and abrasion, both improving equipment’s longevity and increasing production time. Typical industries are mining, material handling, aggregate, dump trucks, material transfer chutes, storage bins, hoppers, and buckets. |

| AR600 |

| AR600 steel plate is the most durable abrasion resistant plate that Jindalai Steel offers. Due to its good abrasion resistance, it is ideal for excessive wear applications. The AR600 surface hardness is 570-640 Brinell Hardness and is often used in mining, aggregate removal, bucket, and high wear applications. |

AR steel is used to help resist material wear and tear include

Conveyors

Buckets

Dump liners

Construction attachments, such as those used on bulldozers and excavators

Grates

Chutes

Hoppers

Brand & Trademark Names

| Wear Plate 400, Wear Plate 450, Wear Plate 500, | RAEX 400, | RAEX 450, |

| RAEX 500, | FORA 400, | FORA 450, |

| FORA 500, | QUARD 400, | QUARD 400, |

| QUARD 450 | DILLIDUR 400 V, DILLIDUR 450 V, DILLIDUR 500 V, | JFE EH 360LE |

| JFE EH 400LE | AR400, | AR450, |

| AR500, | SUMI-HARD 400 | SUMI-HARD 500 |

Since 2008, Jindalai has been keeping research and the accumulation for years of production experience to develop different quality grades of steel to meet market demand, such as ordinary abrasion resistant steel, high-grade abrasion resistant steel and high impact toughness wear-resistant steel plate . At present, abrasion resistant steel plate thickness is between 5-800mm, the hardness of up to 500HBW. Thin steel sheet and ultra-wide steel plate has been developed for special use.