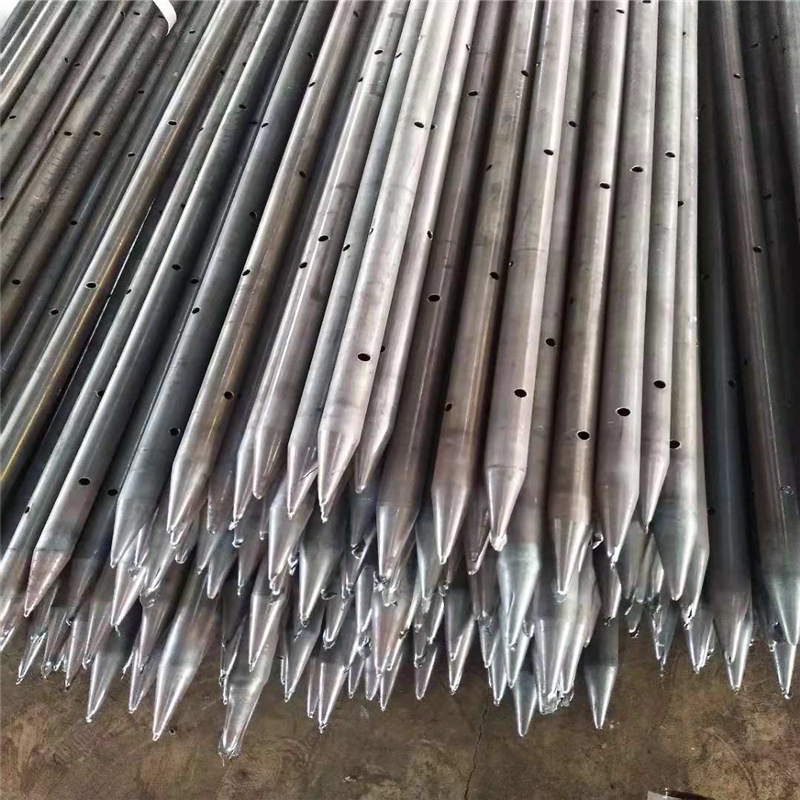

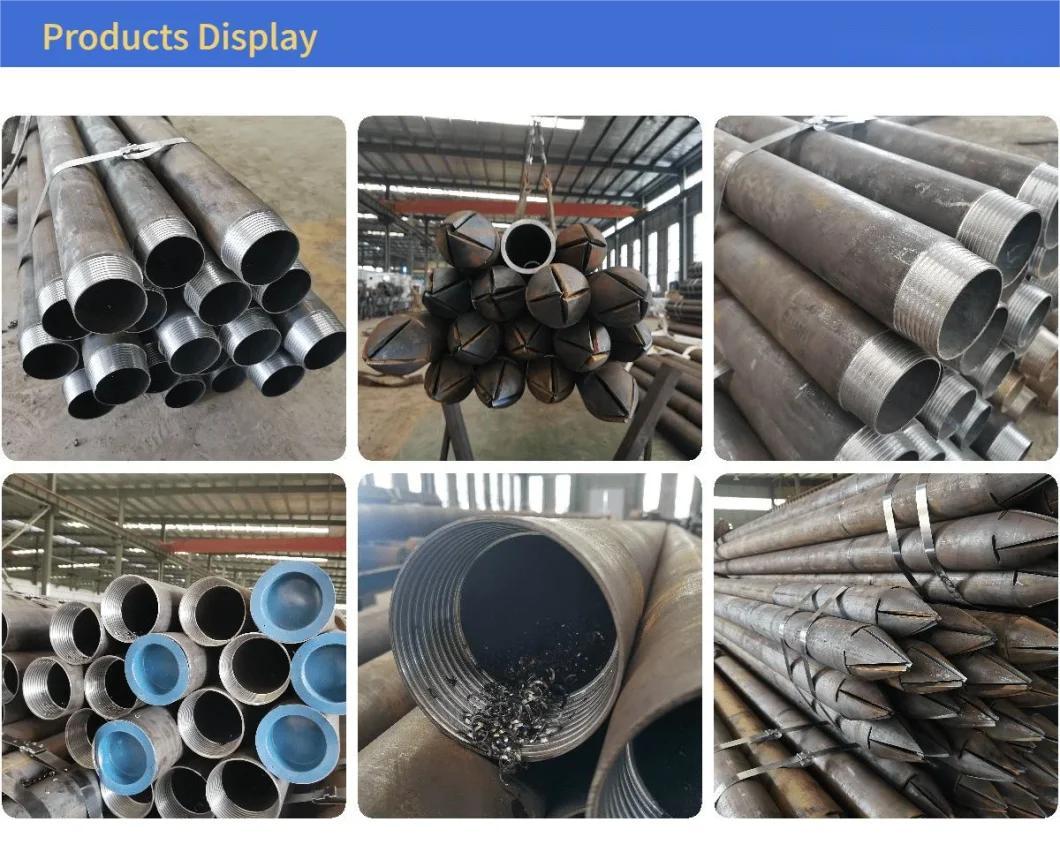

Overview of Grouting Steel Pipe for Bridge Pile Foundation

Grouting steel pipe is a widely used grouting equipment in fields such as architecture, tunnels, and underground engineering. Its main function is to inject grouting materials into underground cavities, fill gaps, and improve the bearing capacity and stability of the foundation. Grouting pipes have the advantages of simple structure, convenient construction, and significant effects, so they have been widely used in underground engineering.

Specification of Grouting Steel Pipe for Bridge Pile Foundation

| Product Name | Steel Pipe Piles/Steel Pipe Poles/Grouting Steel Pipe/Geology Drilling Pipe/Sub-grade Pipe/Micro Pile Tube |

| Standards | GB/T 9808-2008, API 5CT, ISO |

| Grades | DZ40, DZ60, DZ80, R780, J55, K55, N80, L80, P110, 37Mn5, 36Mn2V, 13Cr, 30CrMo, A106 B, A53 B, ST52-4 |

| Outside diameter | 60mm-178mm |

| Thickness | 4.5-20mm |

| Length | 1-12M |

| Bending allowed | No more than 1.5mm/m |

| Process Method | Beveling/Screening/Hole Drilling/Male Threading/Female Threading/Trapezoidal thread/Pointing |

| Packing | Male and Female threading will be protected by plastic clothes or plastic caps Pointer pipe ends will be bare or as per client request. |

| Application | Highway Construction/Metro Construction/Bridge Construction/Mountain Body Fastening Project /Tunnel Portal/Deep Foundation/Underpinning etc. |

| Shipping term | In bulk ships for quantity above 100 tons, Below 100 tons order, will be loaded into containers, For an order below 5 tons, we usually choose LCL (Less than container load) container, to save the cost for client |

| Shipping port | Qingdao port, or Tianjin port |

| Trade term | CIF, CFR, FOB, EXW |

| Paying term | 30%TT + 70% TT against copy of B/L, or 30%TT + 70% LC. |

Common-used Grouting Steel Pipe with Grades

| Grade | C . | Si | Mn . | P ,S | Cu | Ni | Mo | Cr |

| 10 | 0.07-0.14 | 0.17-0.37 | 0.35-0.65 | Max.0.035 | Max.0.25 | Max.0.25 | / | Max.0.15 |

| 20 | 0.17-0.24 | 0.17-0.37 | 0.35-0.65 | Max.0.035 | Max.0.025 | Max.0.25 | / | Max.0.25 |

| 35 | 0.32-0.40 | 0.17-0.37 | 0.50-0.80 | Max.0.035 | Max.0.25 | Max.0.25 | Max.0.25 | |

| 45 | 0.42-0.50 | 0.17-0.37 | 0.50-0.80 | Max.0.035 | Max.0.25 | Max.0.25 | Max.0.25 | |

| 16Mn | 0.12-0.20 | 0.20-0.55 | 1.20-1.60 | Max.0.035 | Max.0.25 | Max.0.25 | Max.0.25 | |

| 12Crmo | 0.08-0.15 | 0.17-0.37 | 0.40-0.70 | Max.0.035 | Max.0.25 | Max.0.30 | 0.40-0.55 | 0.40-0.70 |

| 15Crmo | 0.12-0.18 | 0.17-0.37 | 0.40-0.70 | Max.0.035 | Max.0.25 | Max.0.30 | 0.40-0.55 | 0.80-1.10 |

| 12Cr1Mov | 0.08-0.15 | 0.17-0.37 | 0.40-0.70 | Max.0.035 | Max.0.25 | Max.0.30 | 0.25-0.35 | 0.90-1.20 |

Mechanical Properties

| Grade | Tensile strength (Mpa) | Yield strength(Mpa) | Elongation(%) |

| 10 | ≥335 | ≥205 | ≥24 |

| 20 | ≥390 | ≥245 | ≥20 |

| 35 | ≥510 | ≥305 | ≥17 |

| 45 | ≥590 | ≥335 | ≥14 |

| 16Mn | ≥490 | ≥325 | ≥21 |

| 12CrMo | ≥410 | ≥265 | ≥24 |

| 15CrMo | ≥440 | ≥295 | ≥22 |

| 12Cr1MoV | ≥490 | ≥245 | ≥22 |

Application of grouting steel pipes

Steel grouting pipe is a commonly used pipeline material, widely used in industries, water conservancy, construction, fire protection, and other fields. It has good corrosion resistance and wear resistance, and has a certain compressive strength.

Steel grouting pipes are usually made of stainless steel and therefore have good corrosion resistance. In addition, the steel grouting pipe also has a certain compressive strength and can withstand a certain amount of pressure. In addition, the steel grouting pipe also has wear resistance and can be used for a long time.

-

A106 Crosshole Sonic Logging Welded Tube

-

Steel Round Bar/Steel Rod

-

ASTM A106 Grade B Seamless Pipe

-

A106 GrB Seamless Grouting Steel Pipes for Pile

-

A53 Grouting Steel Pipe

-

Hollow Grouting Spiral Anchor Rod Steel R32

-

R25 Self-Drilling Hollow Grout Injection Anchor...

-

ASTM A312 Seamless Stainless Steel Pipe