Overview of 430 Stainless Steel

SS430 is a ferritic stainless steel with corrosion resistance approaching that of 304/304L stainless steel. This grade does not work harden rapidly and can be formed using both mild stretch forming, bending, or drawing operations. This grade is used in a variety of interior and exterior cosmetic applications where corrosion resistance is more important than strength. SS 430 has poor weldability compared to most stainless steels due to the higher carbon content and lack of stabilizing elements for this grade, which requires post weld heat treatment to restore the corrosion resistance and ductility. Stabilized grades such as SS 439 and 441 should be considered for welded ferritic stainless steel applications.

Specification of 430 Stainless Steel

| Product Name | 430 Stainless Steel Coil | |

| Type | Cold/Hot rolled | |

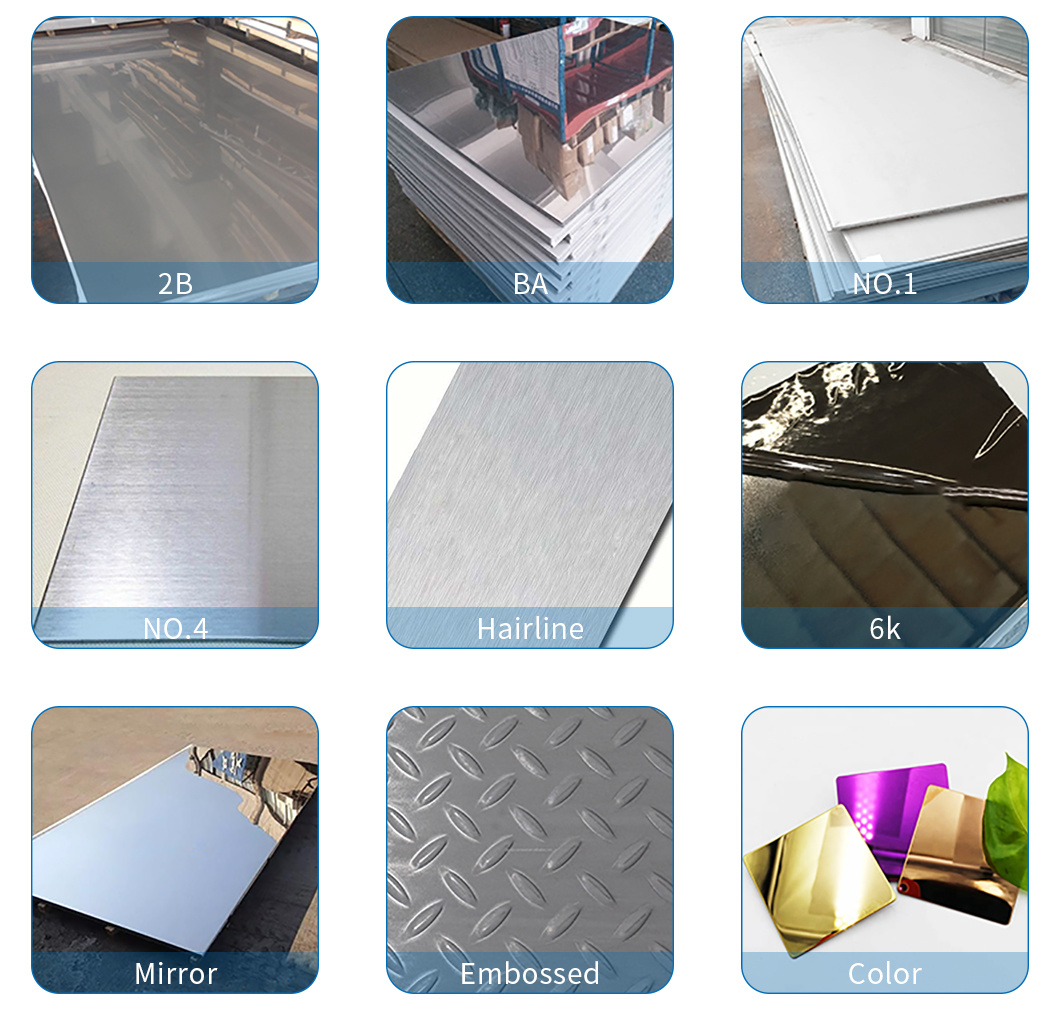

| Surface | 2B 2D BA(Bright Annealed) No1 No3 No4 No5 No8 8K HL(Hair Line) | |

| Grade | 201 / 202 / 301 / 303/ 304 / 304L / 310S / 316L / 316Ti / 316LN / 317L / 318/ 321 / 403 / 410 / 430/ 904L / 2205 / 2507 / 32760 / 253MA / 254SMo / XM-19 / S31803 /S32750 / S32205 / F50 / F60 / F55 / F60 / F61 / F65 etc | |

| Thickness | Cold rolled 0.1mm - 6mm Hot rolled 2.5mm-200mm | |

| Width | 10mm - 2000mm | |

| Application | Construction, Chemical, Pharmaceutical & Bio-Medical, Petrochemical & Refinery, Environmental, Food Processing, Aviation, Chemical Fertilizer, Sewage Disposal, Desalination, Waste Incineration etc. | |

| Processing Service | Machining : Turning / Milling / Planing / Drilling / Boring / Grinding / Gear Cutting / CNC Machining | |

| Deformation processing : Bending / Cutting / Rolling / Stamping Welded / Forged | ||

| MOQ | 1ton. We also can accept sample order. | |

| Delivery time | Within 10-15 workdays after receiving deposit or L/C | |

| Packing | Waterproof paper, and steel strip packed.Standard Export Seaworthy Package. Suit for all kinds of transport, or as required | |

Chemical Composition Mechanical Properties of 430

| ASTM A240/A240M (UNS Designation) | S43000 |

| Chemical Composition | |

| Chromium | 16-18% |

| Nickel (max.) | 0.750% |

| Carbon (max.) | 0.120% |

| Manganese (max.) | 1.000% |

| Silicon (max.) | 1.000% |

| Sulfur (max.) | 0.030% |

| Phosphorus (max.) | 0.040% |

| Mechanical Properties (annealed) | |

| Tensile (min. psi) | 65,000 |

| Yield (min. psi) | 30,000 |

| Elongation (in 2″, min %) | 20 |

| Hardness (max Rb) | 89 |

-

201 304 Color Coated Decorative Stainless Steel...

-

201 Cold Rolled Coil 202 Stainless Steel Coil

-

201 J1 J2 J3 Stainless Steel Coil/Strip Stockist

-

316 316Ti Stainless Steel Coil

-

430 Stainless Steel Coil/Strip

-

8K Mirror Stainless Steel Coil

-

904 904L Stainless Steel Coil

-

Colored Stainless Steel Coil

-

Duplex 2205 2507 Stainless Steel Coil

-

Duplex Stainless Steel Coil

-

Rose Gold 316 Stainless Steel Coil

-

SS202 Stainless Steel Coil/Strip in Stock

-

SUS316L Stainless Steel Coil/Strip