Overview of 316Ti Stainless Steel

316Ti (UNS S31635) is a titanium stabilised version of 316 molybdenum-bearing austenitic stainless steel. The 316 alloys are more resistant to general corrosion and pitting/crevice corrosion than the conventional chromium-nickel austenitic stainless steels such as 304. They also offer higher creep, stress-rupture and tensile strength at elevated temperature. High carbon Alloy 316 stainless steel can be susceptible to sensitisation, the formation of grain boundary chromium carbides at temperatures between approximately 900 and 1500°F (425 to 815°C) which can result in intergranular corrosion. Resistance to sensitisation is achieved in Alloy 316Ti with titanium additions to stabilise the structure against chromium carbide precipitation, which is the source of sensitisation. This stabilisation is achieved by an intermediate temperature heat treatment, during which the titanium reacts with carbon to form titanium carbides. This significantly reduces susceptibility to sensitisation in service by limiting the formation of chromium carbides. Thus, the alloy can be used for extended periods at elevated temperatures without compromising its corrosion resistance. 316Ti has equvilent corrosion resistance to sensitisation as the low carbon version 316L.

Specification of 316Ti Stainless Steel

| Product Name | 316 316Ti Stainless Steel Coil | |

| Type | Cold/Hot rolled | |

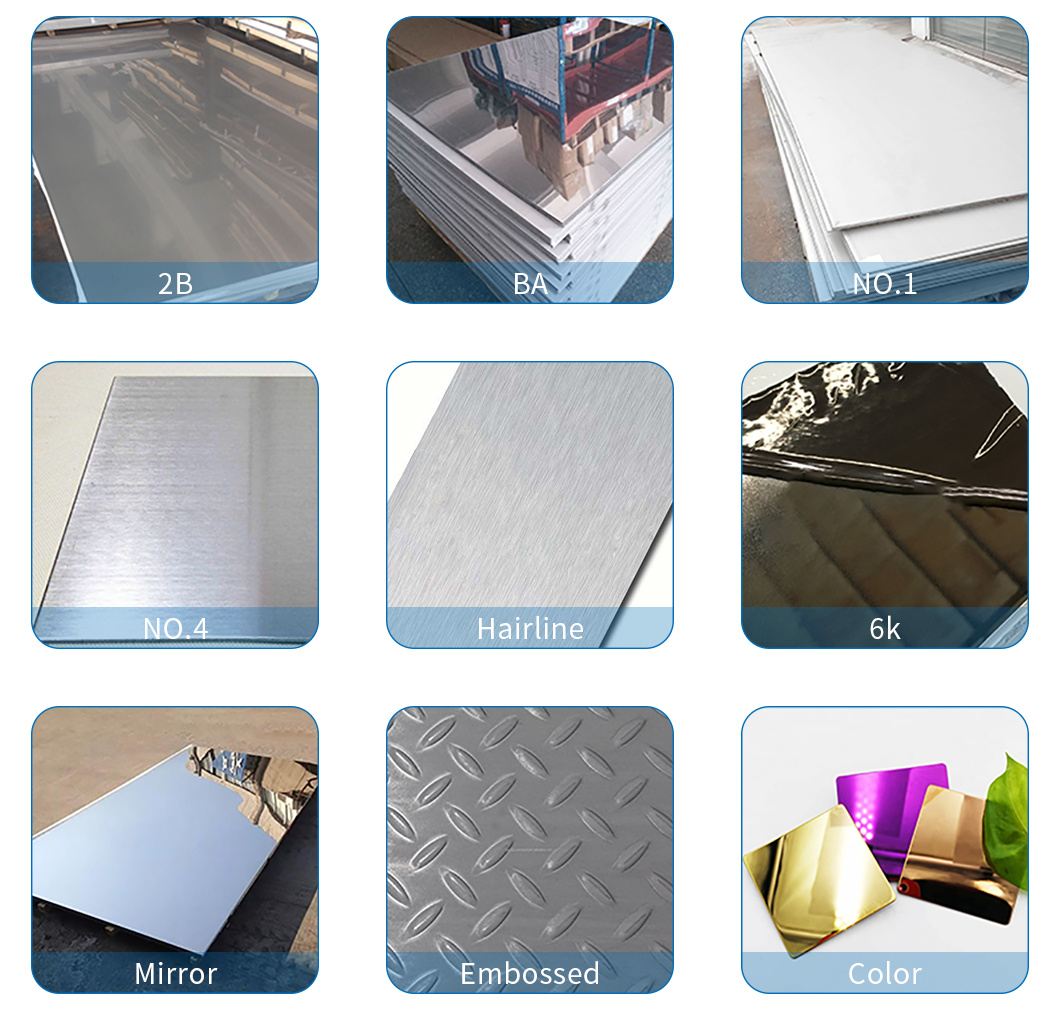

| Surface | 2B 2D BA(Bright Annealed) No1 No3 No4 No5 No8 8K HL(Hair Line) | |

| Grade | 201 / 202 / 301 / 303/ 304 / 304L / 310S / 316L / 316Ti / 316LN / 317L / 318/ 321 / 403 / 410 / 430/ 904L / 2205 / 2507 / 32760 / 253MA / 254SMo / XM-19 / S31803 /S32750 / S32205 / F50 / F60 / F55 / F60 / F61 / F65 etc | |

| Thickness | Cold rolled 0.1mm - 6mm Hot rolled 2.5mm-200mm | |

| Width | 10mm - 2000mm | |

| Application | Construction, Chemical, Pharmaceutical & Bio-Medical, Petrochemical & Refinery, Environmental, Food Processing, Aviation, Chemical Fertilizer, Sewage Disposal, Desalination, Waste Incineration etc. | |

| Processing Service | Machining : Turning / Milling / Planing / Drilling / Boring / Grinding / Gear Cutting / CNC Machining | |

| Deformation processing : Bending / Cutting / Rolling / Stamping Welded / Forged | ||

| MOQ | 1ton. We also can accept sample order. | |

| Delivery time | Within 10-15 workdays after receiving deposit or L/C | |

| Packing | Waterproof paper, and steel strip packed.Standard Export Seaworthy Package. Suit for all kinds of transport, or as required | |

Stainless Steel 316TI coil Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | AFNOR | BS | GOST | EN | |

| SS 316ti | 1.4571 | S31635 | SUS 316ti | Z6CNDT17‐12 | 320S31 | 08Ch17N13M2T | X6CrNiMoTi17-12-2 |

Chemical composition of 316 316L 316Ti

l 316 is characterized by the presence of molybdenum with other stainless steel elements.

l 316L has the same composition as grade 316; only differ by the content of carbon. It is a low carbon version.

l 316Ti is stabilized titanium grade with the presence of molybdenum and other elements.

| Grade | Carbon | Cr | Ni | Mo | Mn | Si | P | S | Ti | Fe |

| 316 | 0.0-0.07% | 16.5-18.5% | 10-13% | 2.00-2.50% | 0.0-2.00% | 0.0-1.0% | 0.0-0.05% | 0.0-0.02% | – | balance |

| 316L | 0.0-0.03% | 16.5-18.5% | 10-13% | 2.00-2.50% | 0.0-2.0% | 0.0-1.0% | 0.0-0.05% | 0.0-0.02% | – | balance |

| 316Ti | 0.0-0.08% | 16.5-18.5% | 10.5-14% | 2.00-2.50% | 0.0-2.00% | 0.0-1.0% | 0.0-0.05% | 0.0-0.03% | 0.40-0.70% | balance |

316ti stainless steel coil Application

316ti stainless steel coil Used in Tractor

316ti stainless steel coil Used in Automotive Trim

316ti stainless steel coil Used in Stamped Machined Products

316ti stainless steel coil Used in Cookware

316ti stainless steel coil Used in Appliances

316ti stainless steel coil Used in Kitchen

316ti stainless steel coil Used in Food service Equipment

316ti stainless steel coil Used in Sinks

316ti stainless steel coil Used in Railway Cars

316ti stainless steel coil Used in Trailers

-

201 304 Color Coated Decorative Stainless Steel...

-

201 Cold Rolled Coil 202 Stainless Steel Coil

-

201 J1 J2 J3 Stainless Steel Coil/Strip Stockist

-

430 Stainless Steel Coil/Strip

-

8K Mirror Stainless Steel Coil

-

316 316Ti Stainless Steel Coil

-

904 904L Stainless Steel Coil

-

Duplex 2205 2507 Stainless Steel Coil

-

Colored Stainless Steel Coil

-

Duplex Stainless Steel Coil

-

Rose Gold 316 Stainless Steel Coil

-

SS202 Stainless Steel Coil/Strip in Stock

-

SUS316L Stainless Steel Coil/Strip