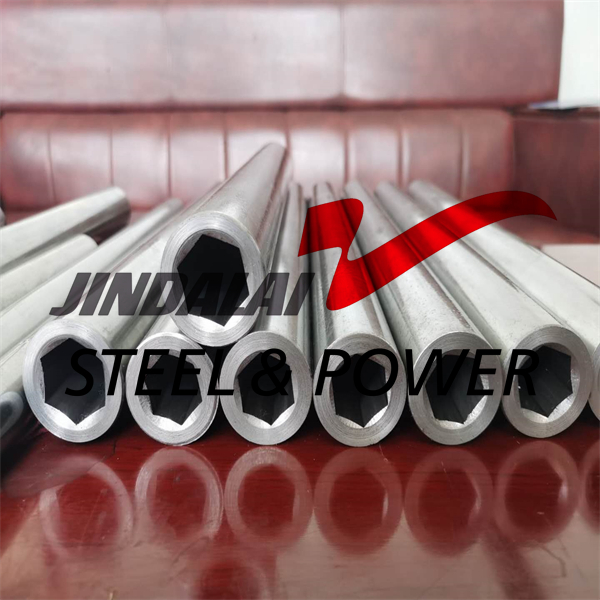

Overview of Stainless Steel Hex Pipes

Hexagonal shaped stainless steel comes in a variety of sizes, and normally specified by width across the flat of hexagon.it is normally cold worked materials.

Stainless Steel Hex Pipes can be used for a wide variety of mechanical applications. It may be used either statically or dynamically. I’s close tolerances, good finish, and dense structure make it ideal for parts such as structural support and parts, frames, racks, trailer beds and trailer components, structural components and supports for buildings, bridges, and highways, conveyors, machine parts, guides, and supports, safety and deck rails, sign posts, athletic equipment, ornamental usages and a wide range of applications in industrial, construction, automotive, appliance, furniture and agricultural industries

Specifications of Stainless Steel Hex Pipe

| stainless steel bright polished pipe/tube | ||

| Steel Grade | 201, 202, 301, 302, 303, 304, 304L, 304H, 309, 309S, 310S, 316, 316L,317L, 321,409L, 410, 410S, 420, 420J1, 420J2, 430, 444, 441,904L, 2205, 2507, 2101, 2520, 2304, 254SMO, 253MA, F55 | |

| Standard | ASTM A213, A312, ASTM A269, ASTM A778, ASTM A789, DIN 17456, DIN17457, DIN 17459, JIS G3459, JIS G3463, GOST9941, EN10216, BS3605,GB13296 | |

| Surface | Polishing, Annealing, Pickling, Bright, Hairline, Mirror, Matte | |

| Type | Hot rolled , Cold rolled | |

| stainless steel round pipe/tube | ||

| Size | Wall thickness | 1mm-150mm(SCH10-XXS) |

| Outer diameter | 6mm-2500mm (3/8"-100") | |

| stainless steel square pipe/tube | ||

| Size | Wall thickness | 1mm-150mm(SCH10-XXS) |

| Outer diameter | 4mm*4mm-800mm*800mm | |

| stainless steel rectangular pipe/tube | ||

| Size | Wall thickness | 1mm-150mm(SCH10-XXS) |

| Outer diameter | 6mm-2500mm (3/8"-100") | |

| Length | 4000mm,5800mm,6000mm,12000mm,or as required. | |

| Trade terms | Price terms | FOB,CIF,CFR,CNF,EXW |

| Payment terms | T/T, L/C, Western union, Paypal, DP, DA | |

| Delivery time | 10-15 days | |

| Export to | Ireland, Singapore, Indonesia, Ukraine, SaudiArabia, Spain, Canada, USA, Brazil, Thailand, Korea, Italy, India, Egypt, Oman, Malaysia, Kuwait, Canada, VietNam, Peru, Mexico, Dubai, Russia, etc | |

| Package | Standard export seaworthy package, or as required. | |

| Container size | 20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High) 24-26CBM 40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High) 54CBM 40ft HC:12032mm(Length)x2352mm(Width)x2698mm(High) 68CBM |

|

Quality Assurance of Stainless Steel Hex Pipe

Basic guarantee

Raw material guarantee, we use the Tsingshan Brand raw material, the quality is good, adding we use the spectrum direct-reading test, our professional workers &equipments, we could guarantee the tubes is right of the clients' needs.

Process control

Follow the process chart adding our workers' care.

Inspection& test

Direct-reading Spectrum Instrument analytic for chemical composition, Yield Strength, Tensile Strength, Elongation, Hardness Test, Flattening Test, Flaring Test, Eddy Current Test, Ultrasonic Test, Hydrostatic Test, Corrosion Test, etc.

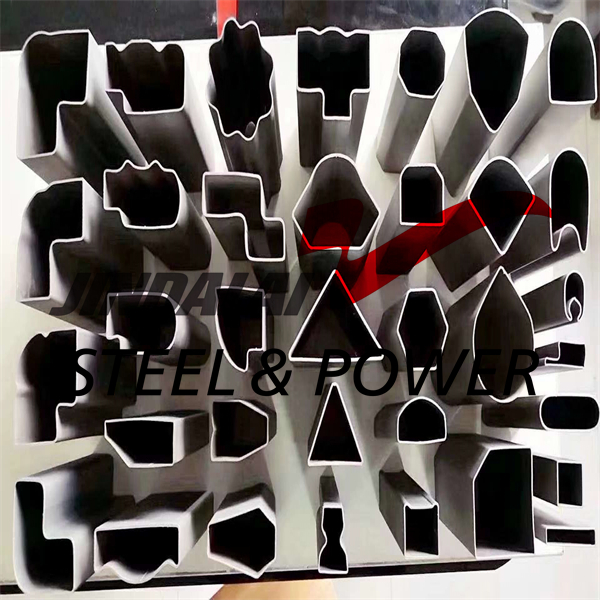

Features of stainless steel Hex tubes

Application of stainless steel Hex tubes

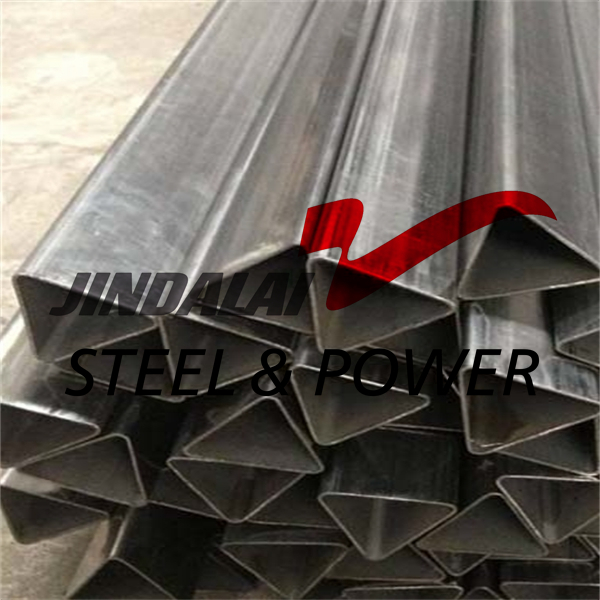

Shaped tubing is widely used by manufactures in automotive, aerospace, construction, drilling, medical equipment, and many other industries. OEMs and metal fabricators currently specify Plymouth Engineered Shapes for such diverse applications as:

Automotive shafts and steering columns.

Tools and tool handles.

Torque wrenches and wrench extensions.

l Telescoping components.

Rebar and direct drilling couplers.

Components for a wide assortment of industrial and medical equipment.