Overview of 201 Stainless Steel

Type 201 stainless steel is a mid-range product with a variety of useful qualities. While it is ideal for certain uses, it is not a good choice for structures that may be prone to corrosive forces such as saltwater.

Type 201 is part of the 200 series of austenitic stainless steel. Originally developed to conserve nickel, this family of stainless steels is characterized by low nickel content.

Type 201 can substitute for type 301 in many applications, but it's less resistant to corrosion than its counterpart, particularly in chemical environments.

Annealed, it is non-magnetic, but type 201 can become magnetic by cold working. Greater nitrogen content in type 201 provides higher yield strength and toughness than type 301 steel, especially at low temperatures.

Type 201 is not hardened by heat treatment and is annealed at 1850-1950 degrees Fahrenheit (1010-1066 degrees Celsius), followed by water quenching or rapid air cooling.

Type 201 is used to produce a range of household appliances, including sinks, cooking utensils, washing machines, windows, and doors. It is also used in automotive trim, decorative architecture, railway cars, trailers, and clamps. It is not recommended for structural outdoor applications because of its susceptibility to pitting and crevice corrosion.

Specification of of 201 Stainless Steel

|

Standard |

ASTM,AISI,SUS,JIS,EN,DIN,BS,GB,etc. |

|

Material |

201, 202, 301, 302, 303, 304, 304L, 304H, 310S, 316, 316L, 317L, 321, 310S, 309S, 410, 410S,420, 430, 431, 440A, 904L, 2205, 2507,ect. |

|

Thickness |

Cold rolled:0.1mm-3.0mm |

|

Hot rolled: 3.0mm-200mm |

|

|

As Your Request |

|

|

Width |

Hot rolled regular width:1500,1800,2000, As Your Request |

|

Cold rolled regular width:1000,1219,1250,1500,As Your Request |

|

|

Technique |

Hot rolled / cold rolled |

|

Length |

1-12m or as Your Request |

|

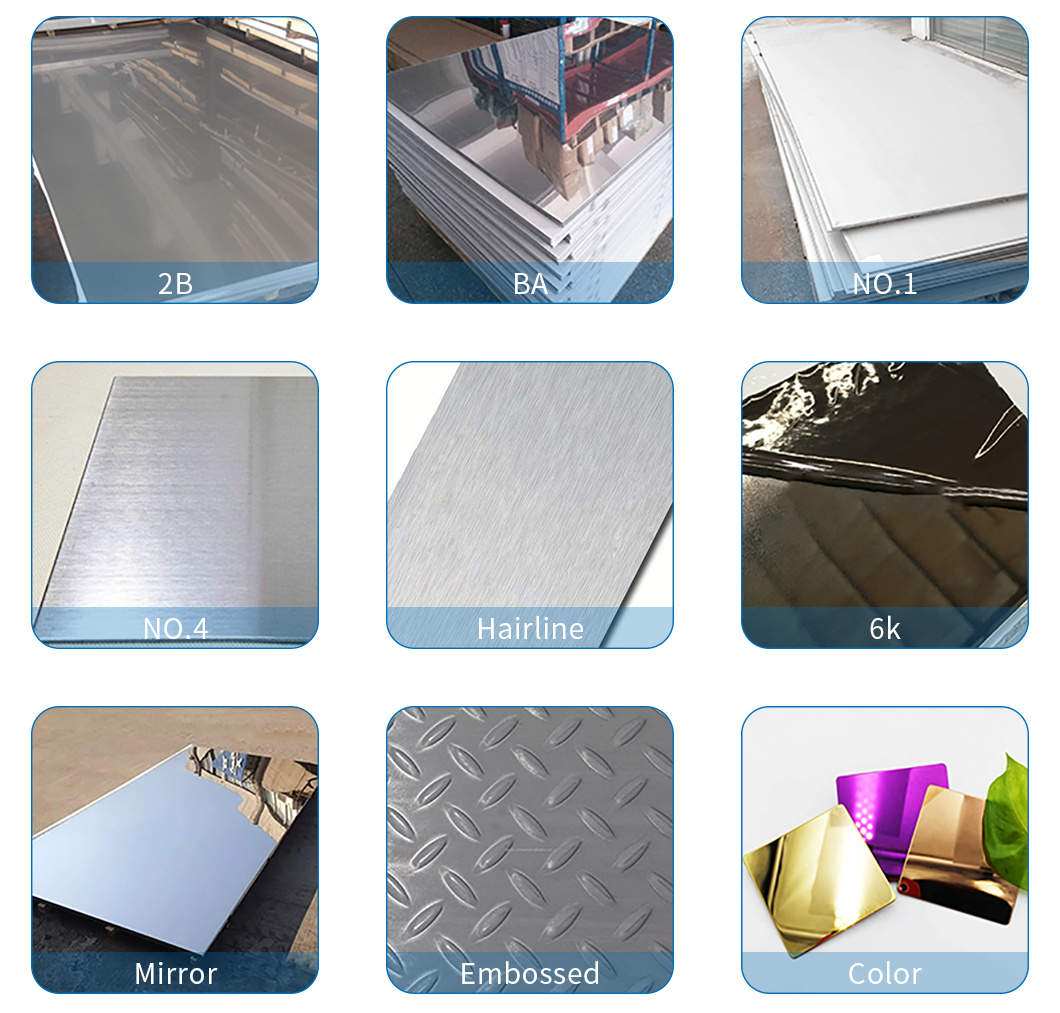

Surface |

2B,BA(bright annealed) NO.1 NO.2 NO.3 NO.4,2D, 4K, 6K, 8K HL(Hair Line), SB, Embossed,as your request |

|

Packing |

Standard Sea-worthy Packing / As Your Request |

Types of SS201

l J1(Mid Copper): The carbon content is slightly higher than J4 and the copper content is lower than J4. Its processing performance is less thanJ4. It is suitable for ordinary shallow drawing and deep drawing products, such as decorative board, sanitary products, sink,product tube, etc.

l J2, J5:Decorative tubes: Simple decorative tubes are still good, because the hardness is high (both above 96°) and the polishing is morebeautiful, but the square tube or the curved tube (90°) is prone to bursting.

l In terms of flat plate: due to the high hardness, the board surface is beautiful, and the surface treatment such as frosting,

l polishing and plating is acceptable. But the biggest problem is the bending problem, the bend is easy to break, and the groove is easy to burst. Poor extensibility.

l J3(Low Copper): Suitable for decorative tubes. Simple processing can be done on the decorative panel, but it is not possible with a little difficulty. There is feedback that the shearing plate is bent, and there is an inner seam after breaking (black titanium,color plate series, sanding plate, broken, folded out with inner seam). The sink material has been tried to bend, 90 degrees, but it will not continue.

l J4( High Copper): It is the higher end of the J series. It is suitable for small angle types of deep drawing products. Most of the products that require deep salt picking and salt spray test will choose it. For example, sinks, kitchen utensils, bathroom products, water bottles, vacuum flasks, door hinges, shackles, etc.

Chemical Composition of 201 Stainless Steel

| Grade | C % | Ni % | Cr % | Mn % | Cu % | Si % | P % | S % | N % | Mo % |

| 201 J1 | 0.104 | 1.21 | 13.92 | 10.07 | 0.81 | 0.41 | 0.036 | 0.003 | - | - |

| 201 J2 | 0.128 | 1.37 | 13.29 | 9.57 | 0.33 | 0.49 | 0.045 | 0.001 | 0.155 | - |

| 201 J3 | 0.127 | 1.30 | 14.50 | 9.05 | 0.59 | 0.41 | 0.039 | 0.002 | 0.177 | 0.02 |

| 201 J4 | 0.060 | 1.27 | 14.86 | 9.33 | 1.57 | 0.39 | 0.036 | 0.002 | - | - |

| 201 J5 | 0.135 | 1.45 | 13.26 | 10.72 | 0.07 | 0.58 | 0.043 | 0.002 | 0.149 | 0.032 |

-

201 304 Color Coated Decorative Stainless Steel...

-

201 Cold Rolled Coil 202 Stainless Steel Coil

-

201 J1 J2 J3 Stainless Steel Coil/Strip Stockist

-

316 316Ti Stainless Steel Coil

-

430 Stainless Steel Coil/Strip

-

8K Mirror Stainless Steel Coil

-

904 904L Stainless Steel Coil

-

Colored Stainless Steel Coil

-

Duplex 2205 2507 Stainless Steel Coil

-

Duplex Stainless Steel Coil

-

Rose Gold 316 Stainless Steel Coil

-

SS202 Stainless Steel Coil/Strip in Stock

-

SUS316L Stainless Steel Coil/Strip