Overview of Stainless Steel 201

Stainless Steel commonly uses 201, 202, 304, 316L, and 430; these five types of stainless steel as material. According to different uses and budgets, Jindalail Steel will recommend the most suitable substrates for processing. For example, the stainless steel plate used in the decoration industry, Jindalaill Steel usually uses 304, 201, 316L stainless steel. The 316L material has excellent corrosion resistance and is more suitable for the building near the beach or outdoors. For stainless steel trim, profile or channel, 304 is the best material, and its good ductility can withstand difficult processing, such as bending, laser cutting, welding, etc., Such as the production of T6 profiles, the failure risk of using 201 material is 3-4 times higher than that of 304. In the magnetic industry, there is no doubt that 430 material is the only choice. Jindalaill Steel can produce products with different shapes and different color surfaces according to customer needs.

Specification of Stainless Steel 201

| Product Name | 201 stainless steel coil |

| Grades | 201/EN 1.4372/SUS201 J1 J2 J3 J4 J5 |

| Hardness | 190-250HV |

| Thickness | 0.1mm-200.0mm |

| Width | 1.0mm-1500mm |

| Edge | Slit/Mill |

| Quantity Tolerance | ±10% |

| Paper Core Internal Diameter | Ø500mm paper core, special internal diameter core and without paper core on customer request |

| Surface Finish | NO.1/2B/2D/BA/HL/Brushed/6K/8K Mirror,etc |

| Packaging | Wooden Pallet/Wooden Case |

| Payment Terms | 30% TT deposit and 70% balance against a copy of B/L, 100% LC at sight |

| Delivery Time | 10-15 working days |

| MOQ | 1000Kgs |

| Shipping Port | QINGDAO/TIANJIN port |

| Sample | The sample of 201 stainless steel coil is available |

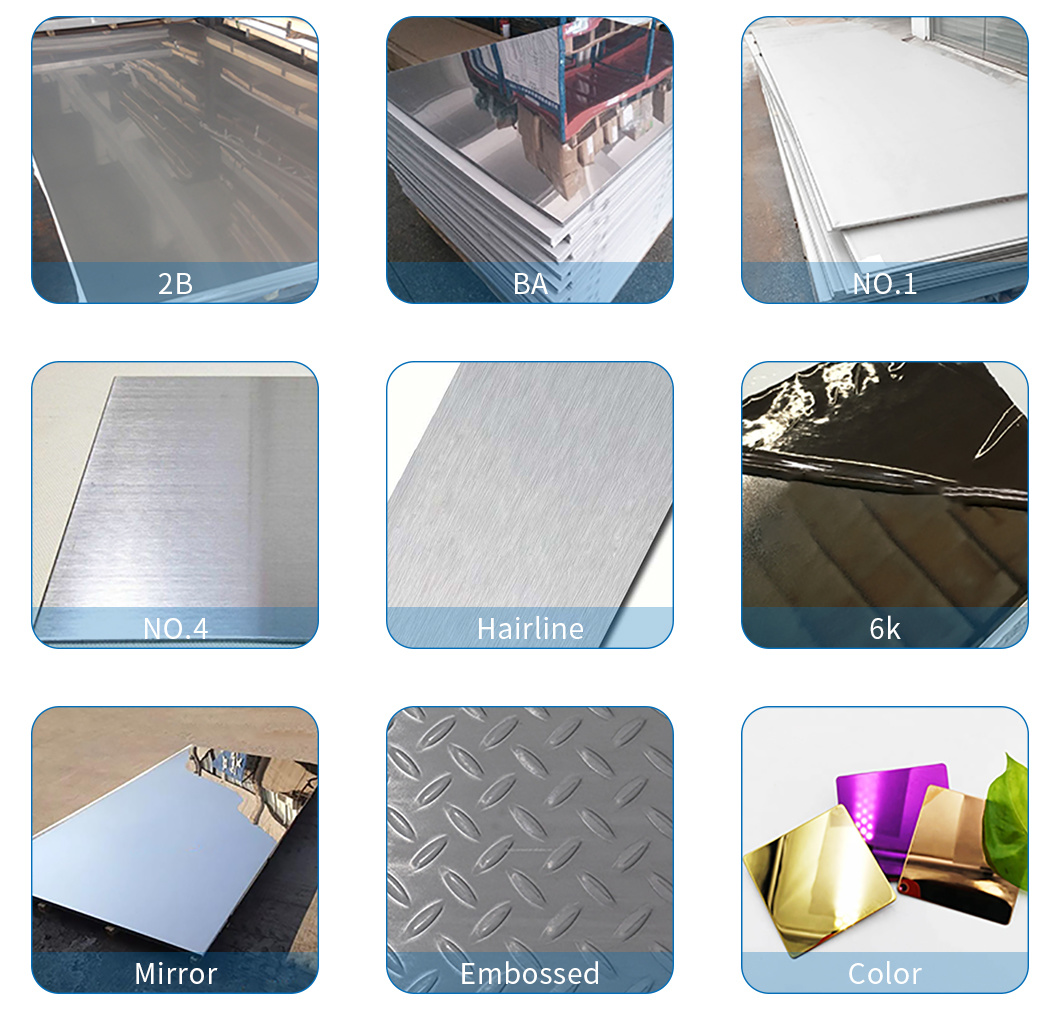

Surface Treatment of Stainless Steel

| Surface | Characteristic | Summary of Manufacturing Method | Application |

| NO.1 | Silvery white | Hot rolled to specified thickness | Do not need to have a glossy surface use |

| lackluster | |||

| NO.2D | Silvery white | After cold rolling, heat treatment and pickling are carried out | General material, deep material |

| NO.2B | Gloss is stronger than No.2D | After No.2D treatment, the final light cold rolling is carried out through the polishing roller | The general material |

| BA | As bright as a sixpence | No standard, but usually a bright annealed surface with high reflectivity. | Building materials, kitchen utensils |

| NO.3 | Rough lapping | Grind with 100~200# (unit) strop tape | Building materials, kitchen utensils |

| NO.4 | Intermediate grinding | Polished surface obtained by grinding with 150~180# strop abrasive tape | Building materials, kitchen utensils |

| NO.240 | Fine lapping | Grinding with 240# strop abrasive tape | kitchenware |

| NO.320 | Very fine grinding | Grinding was carried out with 320# strop abrasive tape | kitchenware |

| NO.400 | The luster is close to BA | Use 400# polishing wheel to grind | General timber, building timber, kitchen appliances |

| HL | Hairline grinding | Suitable particle material for hair stripe grinding (150~240#) with many grains | Building, construction material |

| NO.7 | It's close to mirror grinding | Use a 600# rotary polishing wheel to grind | For art or decoration |

| NO.8 | Mirror ultrafinish | The mirror is ground with a polishing wheel | Reflector, for decoration |

Advantage of JINDALAI STEEL GROUP

l We have processing machines for OEM and customized.

l We have all kinds of stainless steel materials large stocks, and we fast delivery materials to customers.

l We are a steel factory, so we have price advantage.

l We have professional sales and production team, so we supply quality guarantee.

l Cheap logistics cost to the port from our factory.

-

201 304 Color Coated Decorative Stainless Steel...

-

201 Cold Rolled Coil 202 Stainless Steel Coil

-

201 J1 J2 J3 Stainless Steel Coil/Strip Stockist

-

316 316Ti Stainless Steel Coil

-

430 Stainless Steel Coil/Strip

-

8K Mirror Stainless Steel Coil

-

904 904L Stainless Steel Coil

-

Colored Stainless Steel Coil

-

Duplex 2205 2507 Stainless Steel Coil

-

Duplex Stainless Steel Coil

-

Rose Gold 316 Stainless Steel Coil

-

SS202 Stainless Steel Coil/Strip in Stock

-

SUS316L Stainless Steel Coil/Strip